Submersible Pumps

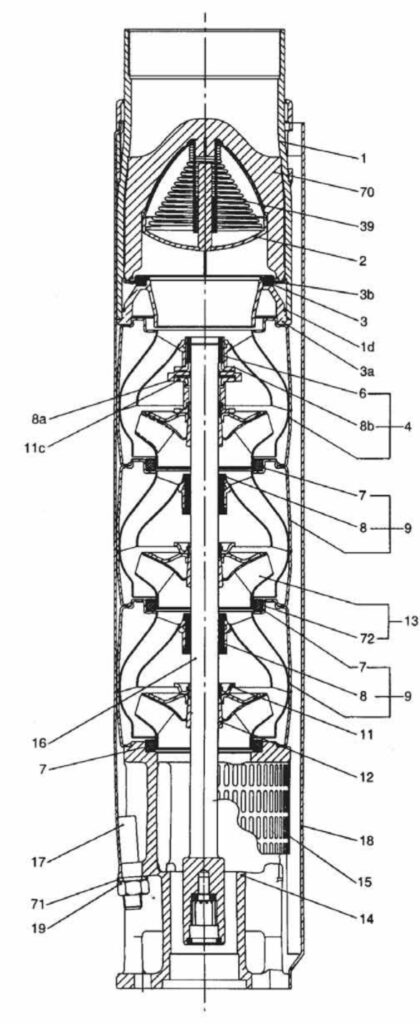

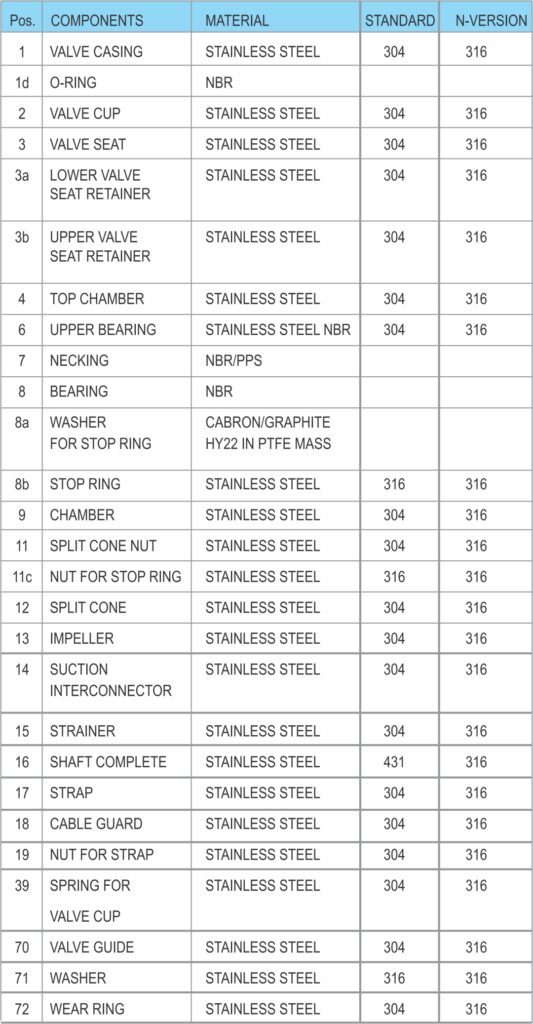

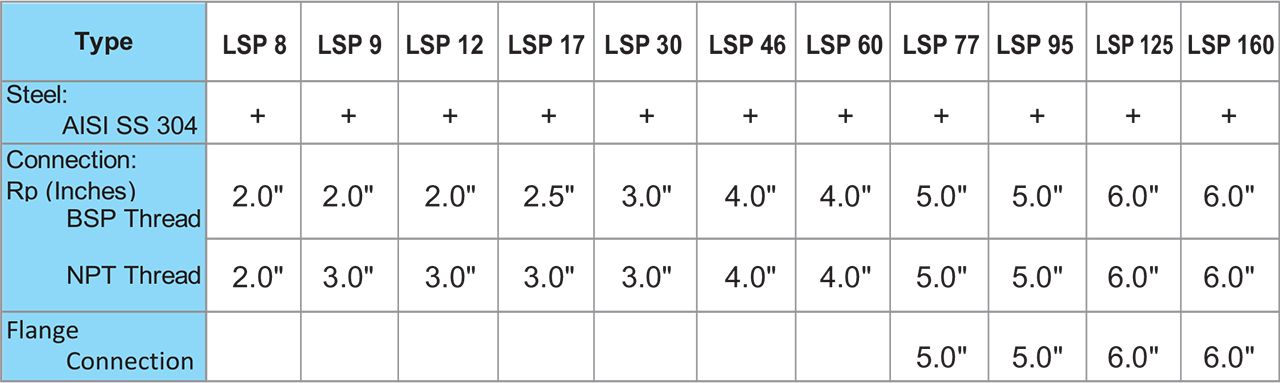

Material Specification

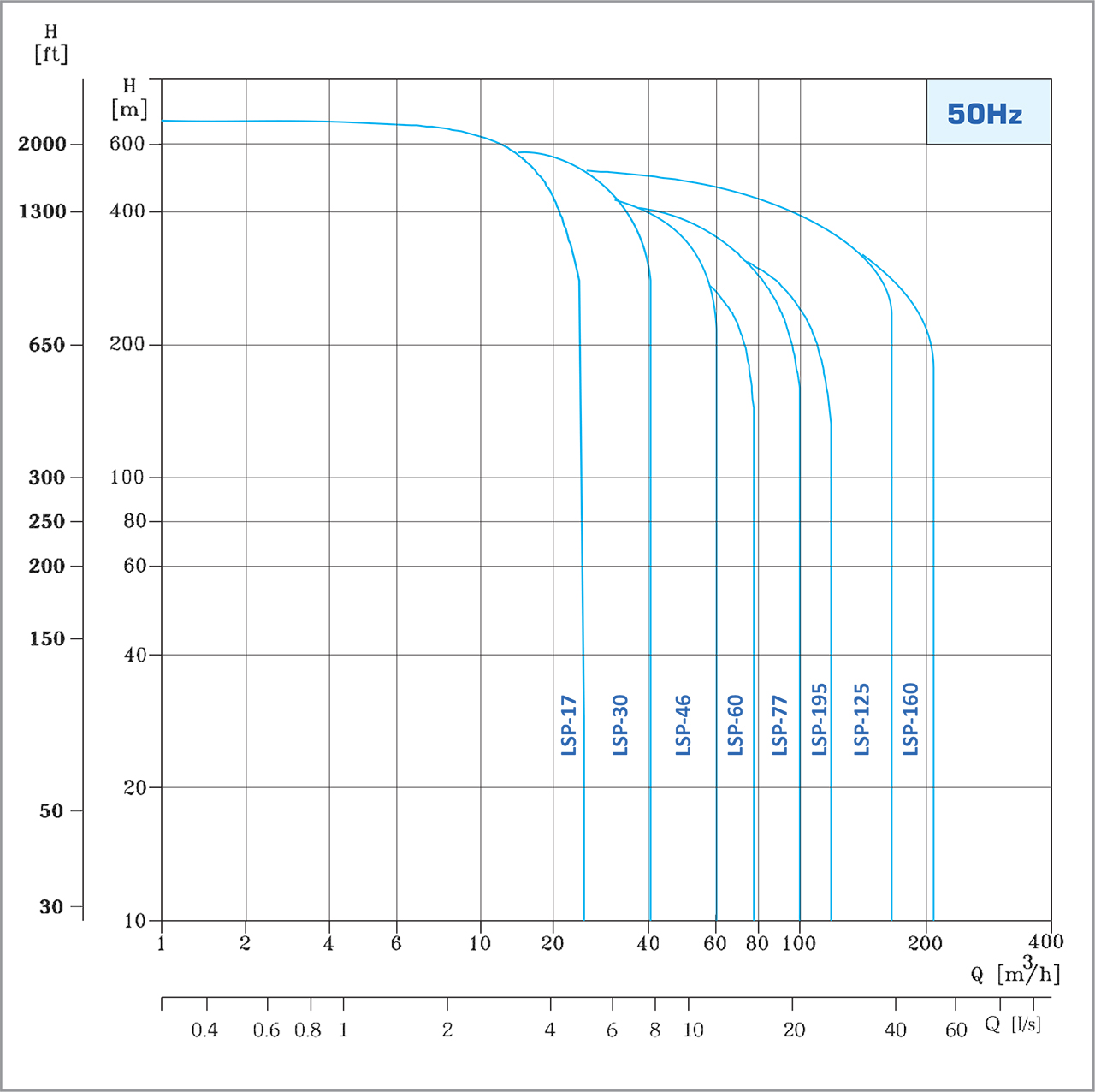

Performance Range of LSP Series

Submersible Pump & Motors LSP Series

Pump Range

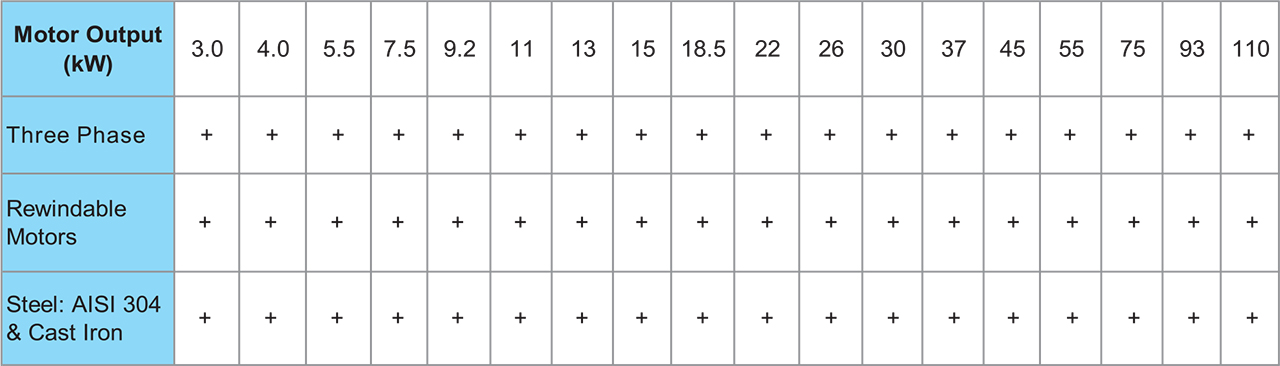

Motor Range

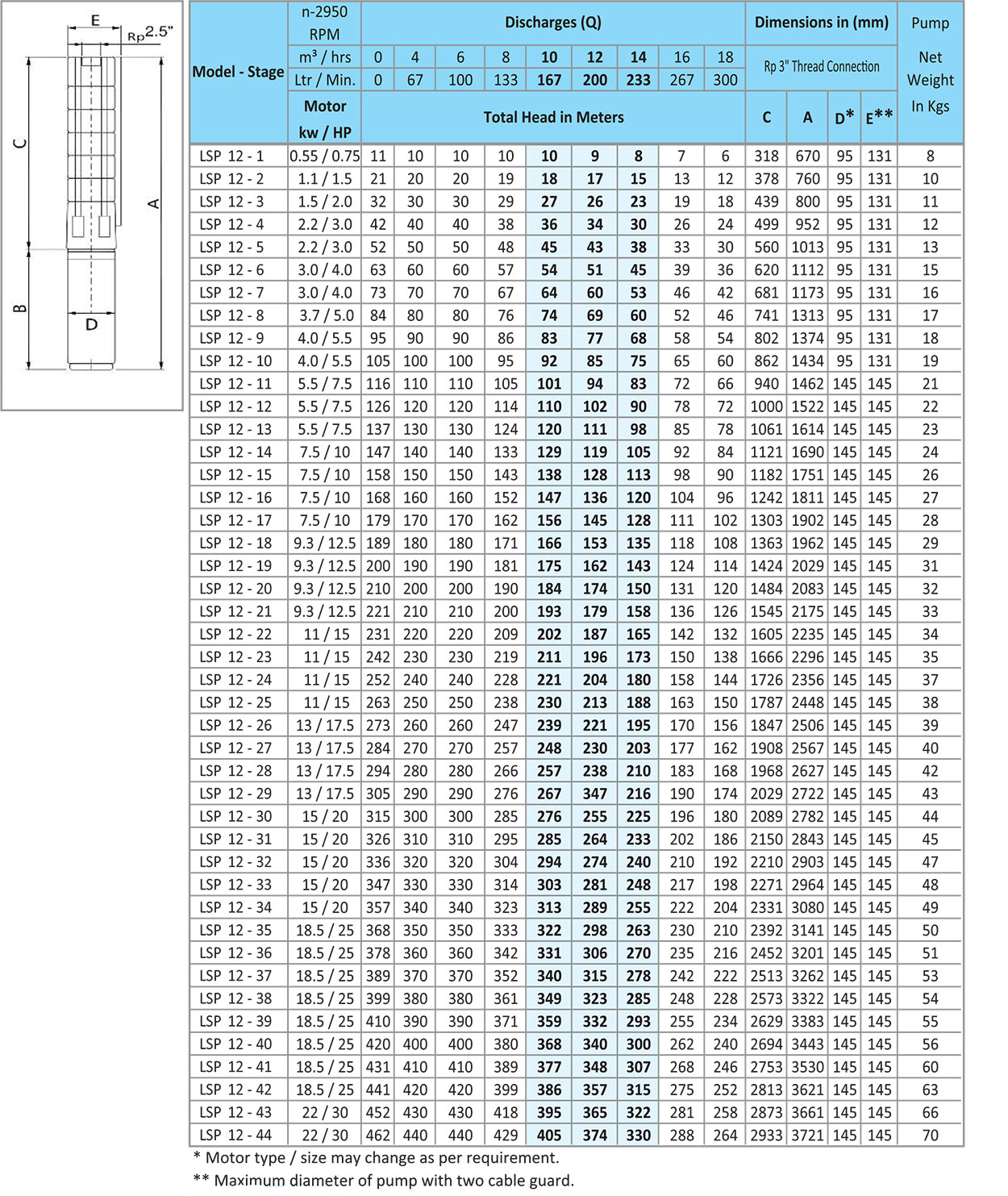

Direct – on – Line starting is recommended up to 7.5 kW.

Soft starter or autotransformer is recommended above 7.5 kW.

Submersible Pump LSP Series

Applications

The Pumps are suitable for the following applications:

- raw water supply

- irrigation supply

- groundwater lowering

- pressure boosting

- industrial applications

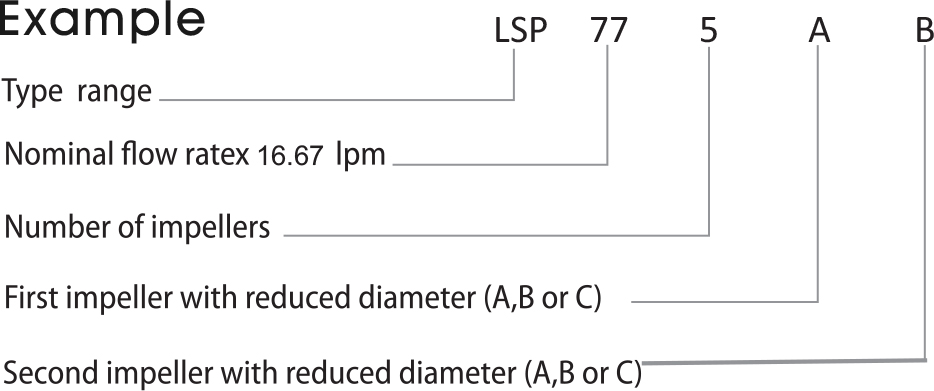

Type Key

Pumped Liquids

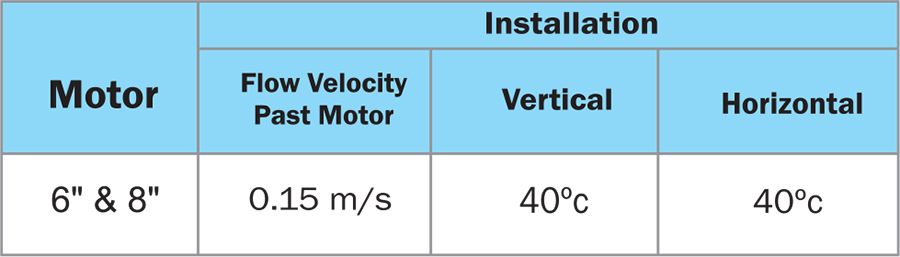

Operating Conditions

Head H: max.670m

Maximum Liquid Temperature

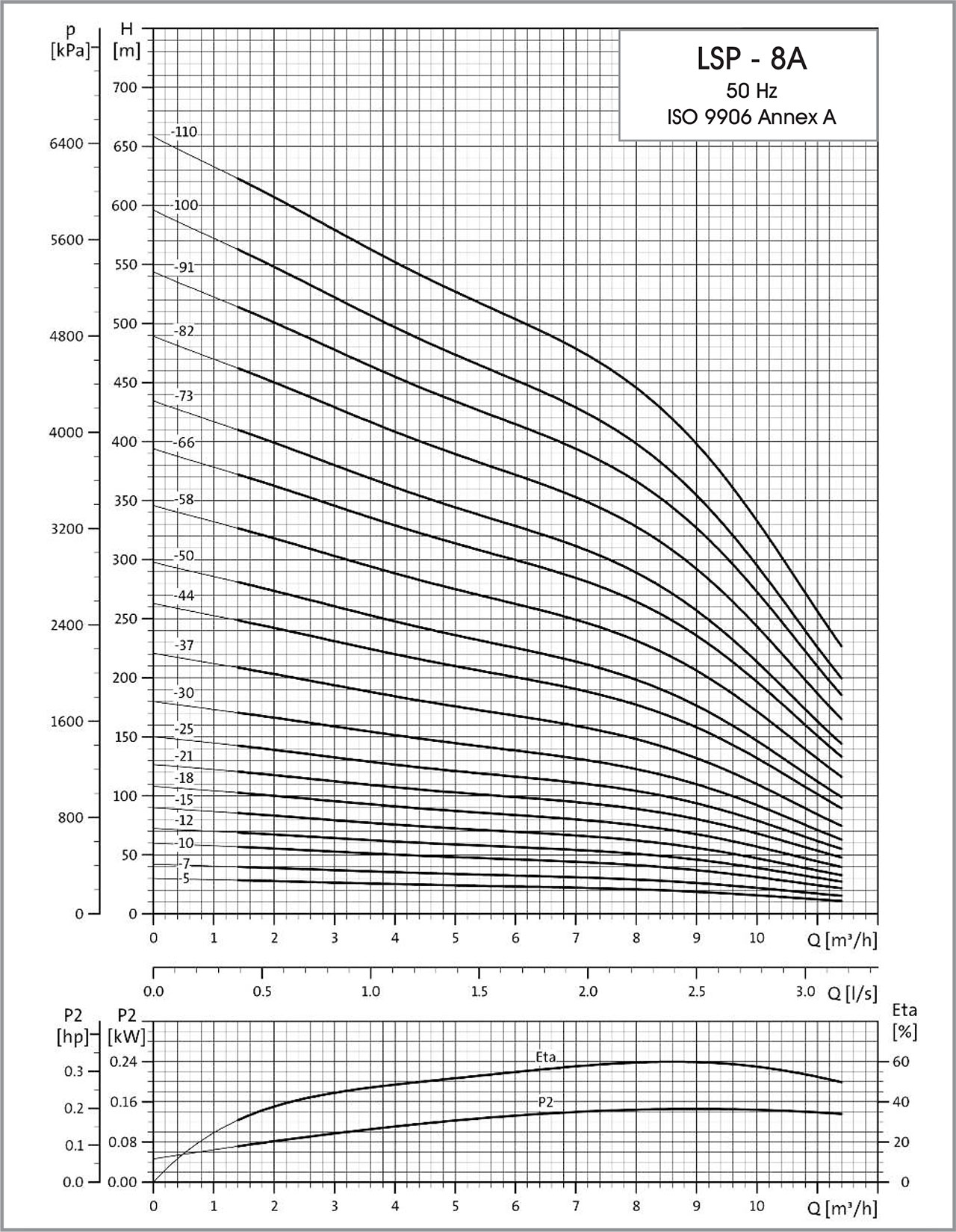

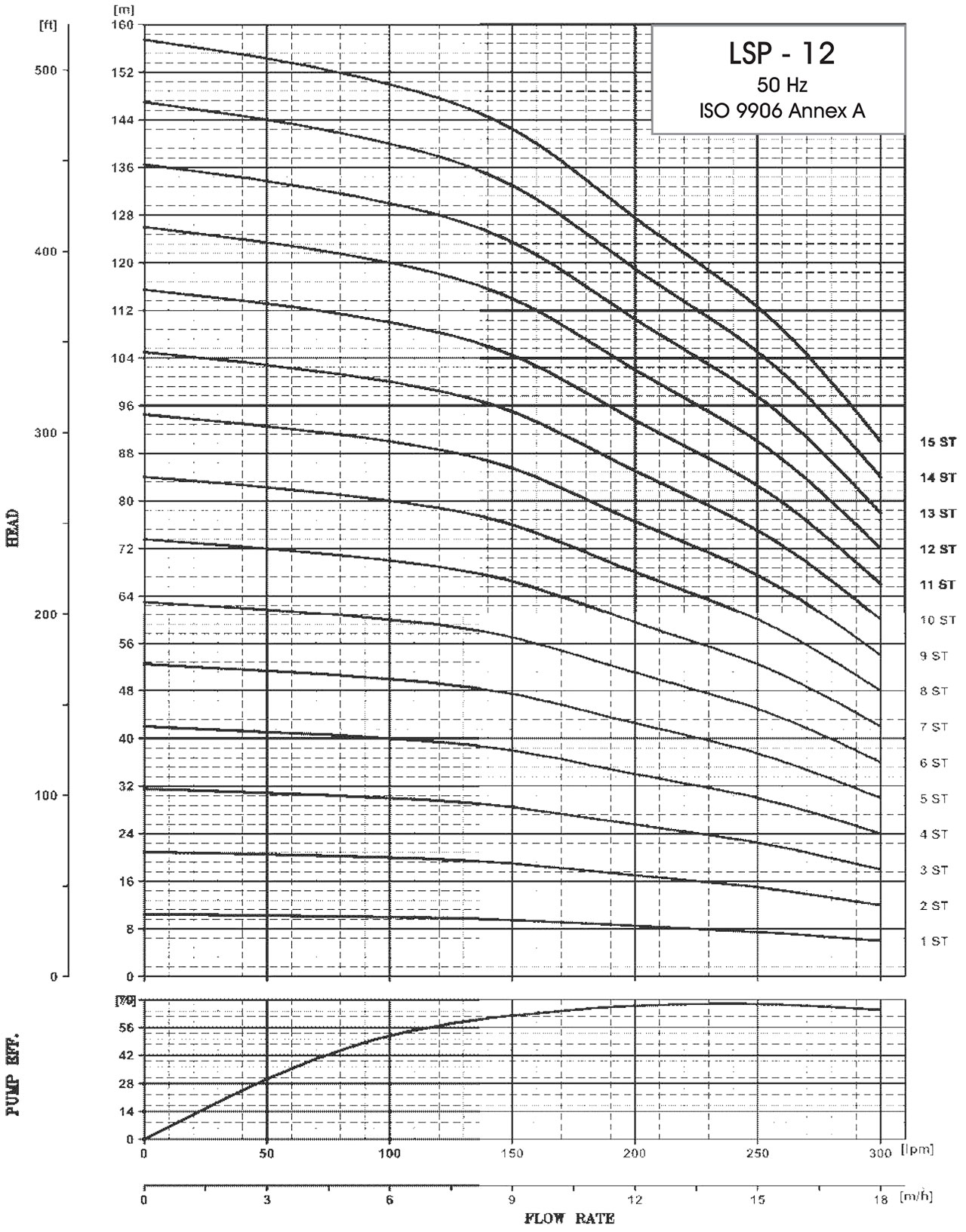

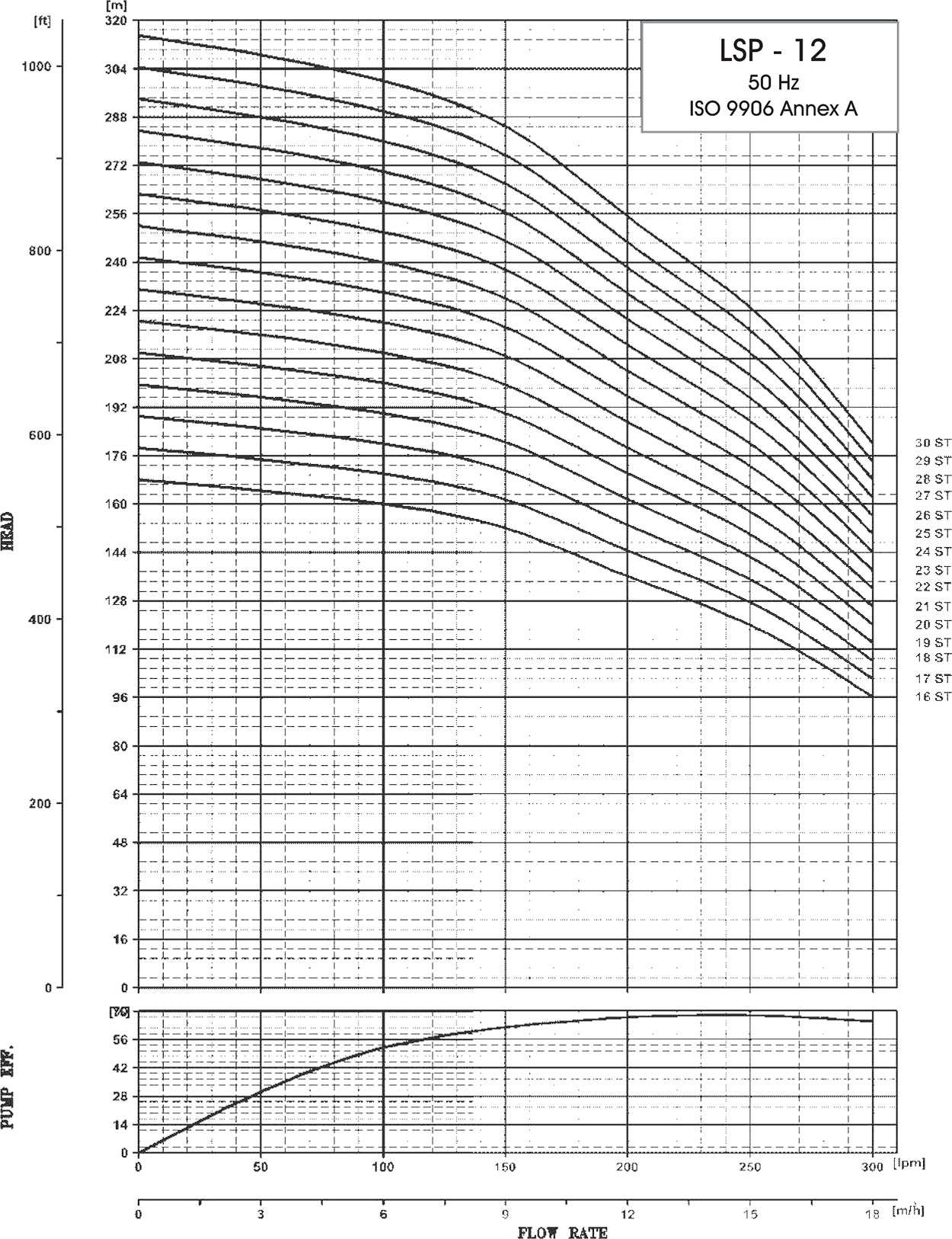

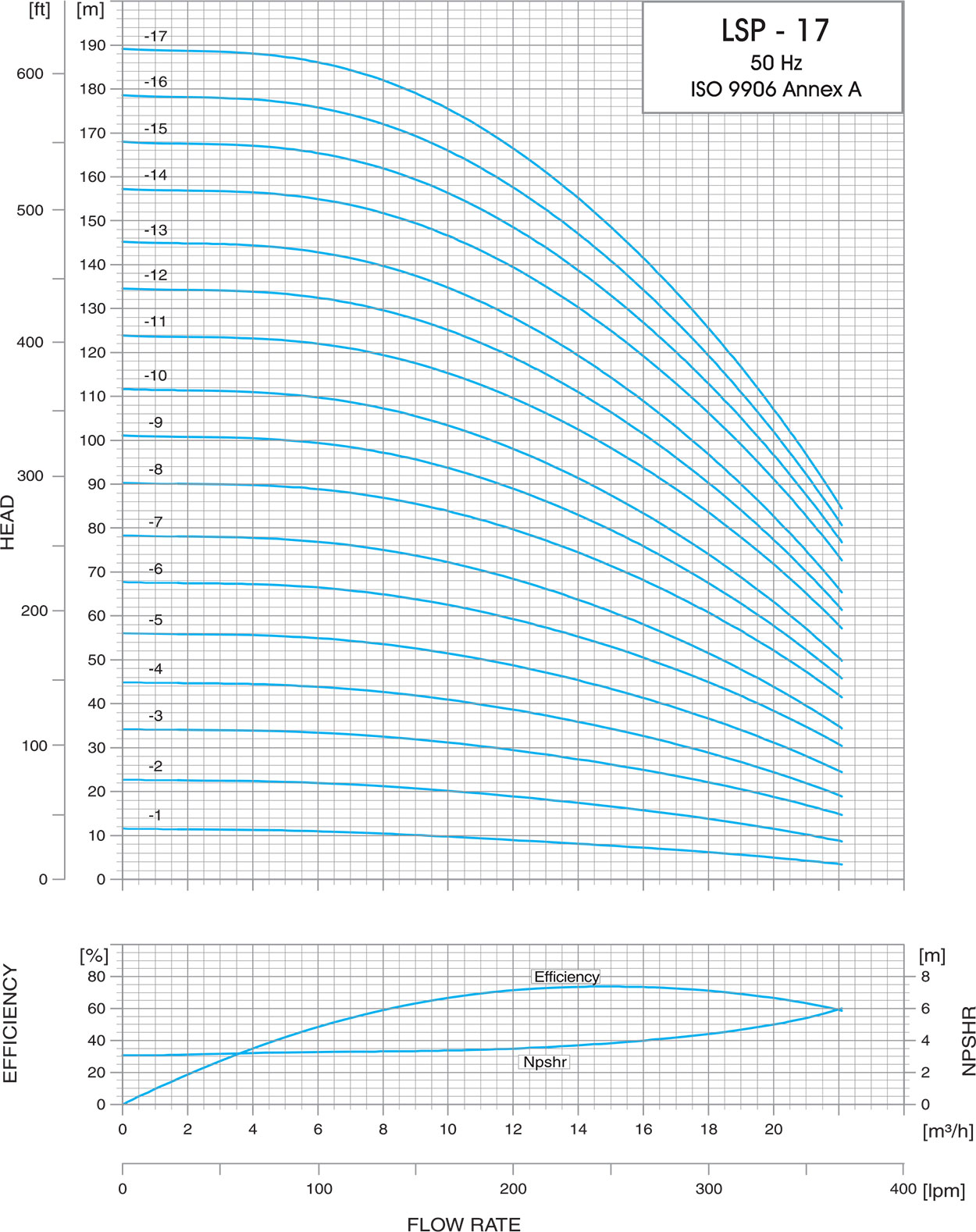

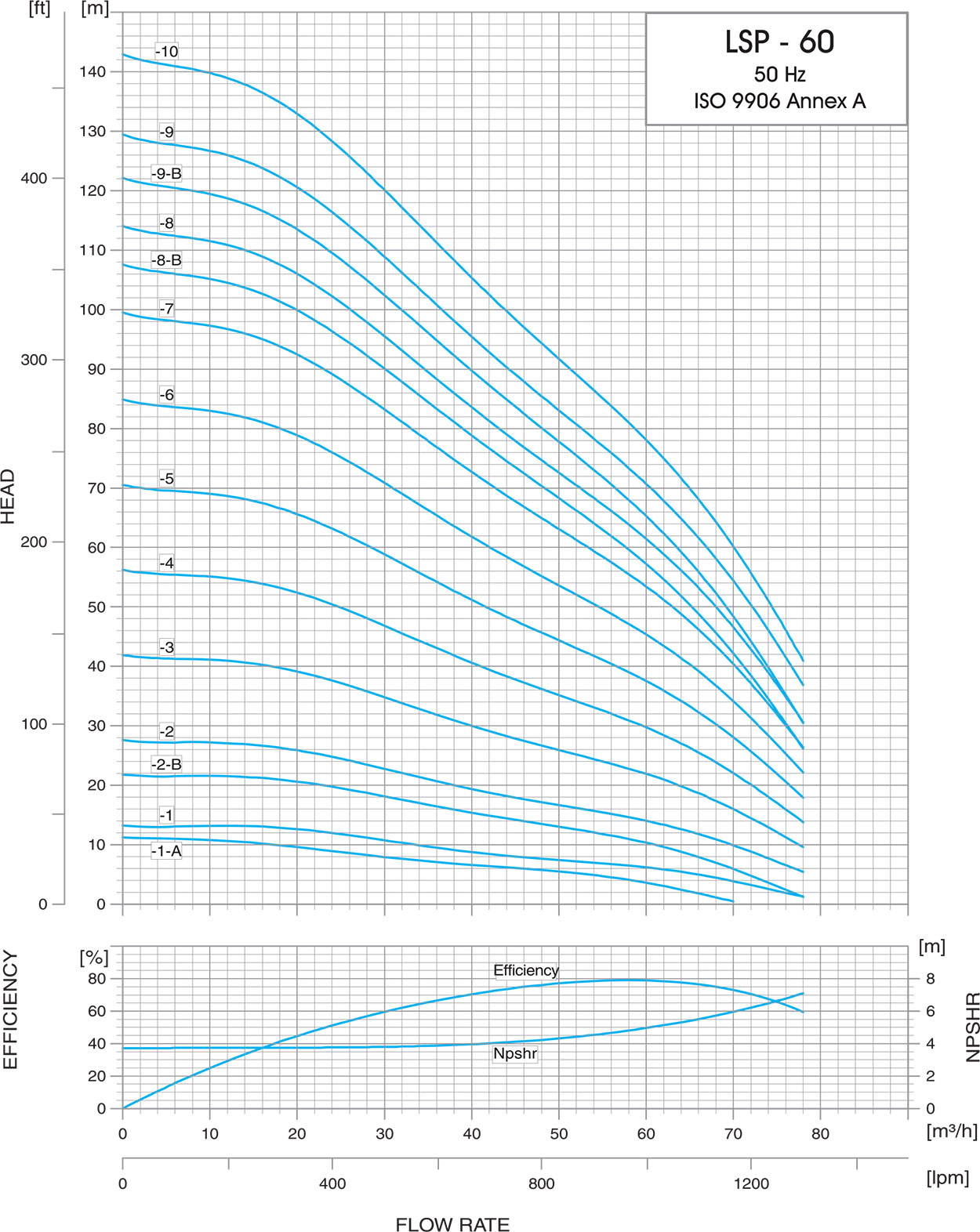

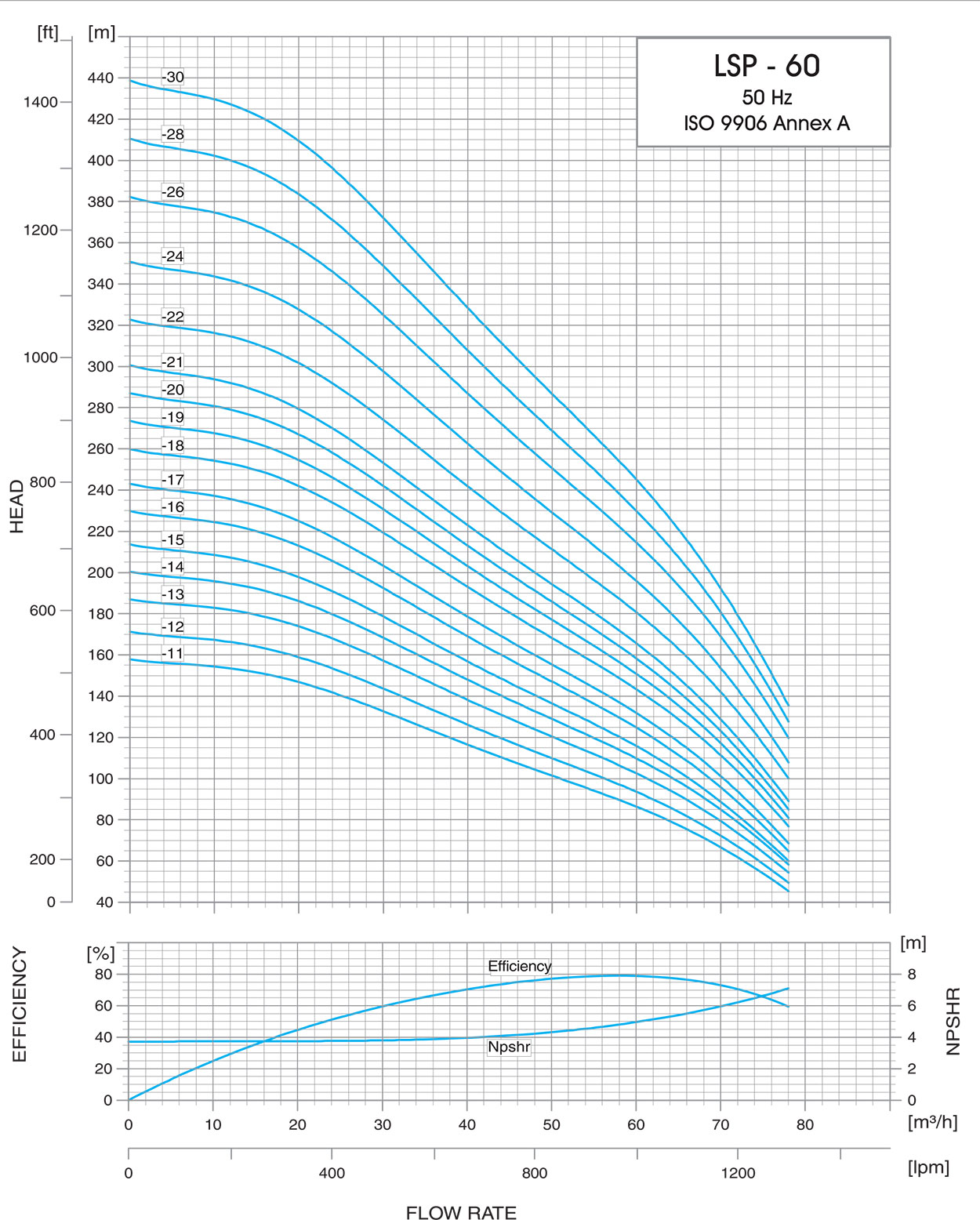

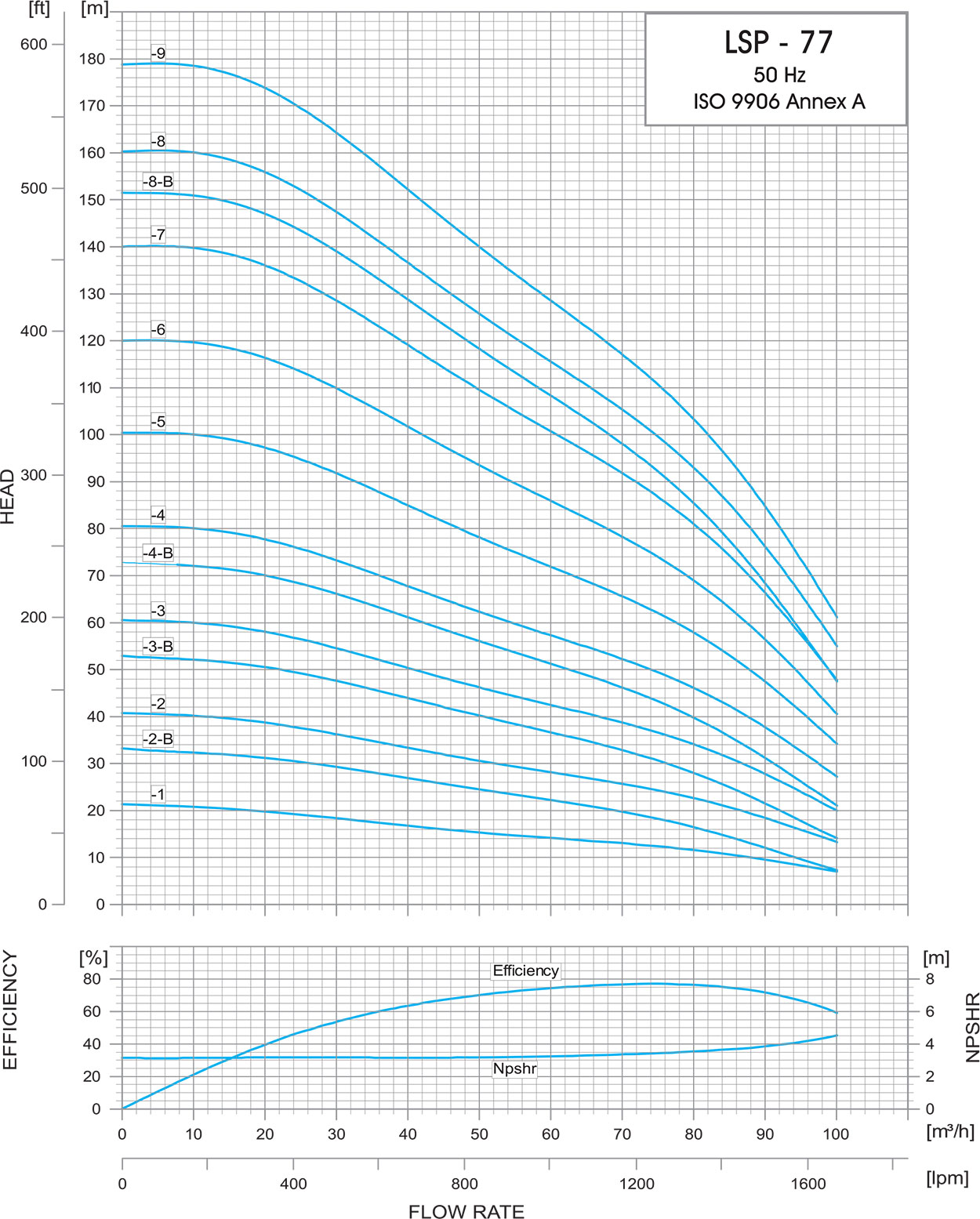

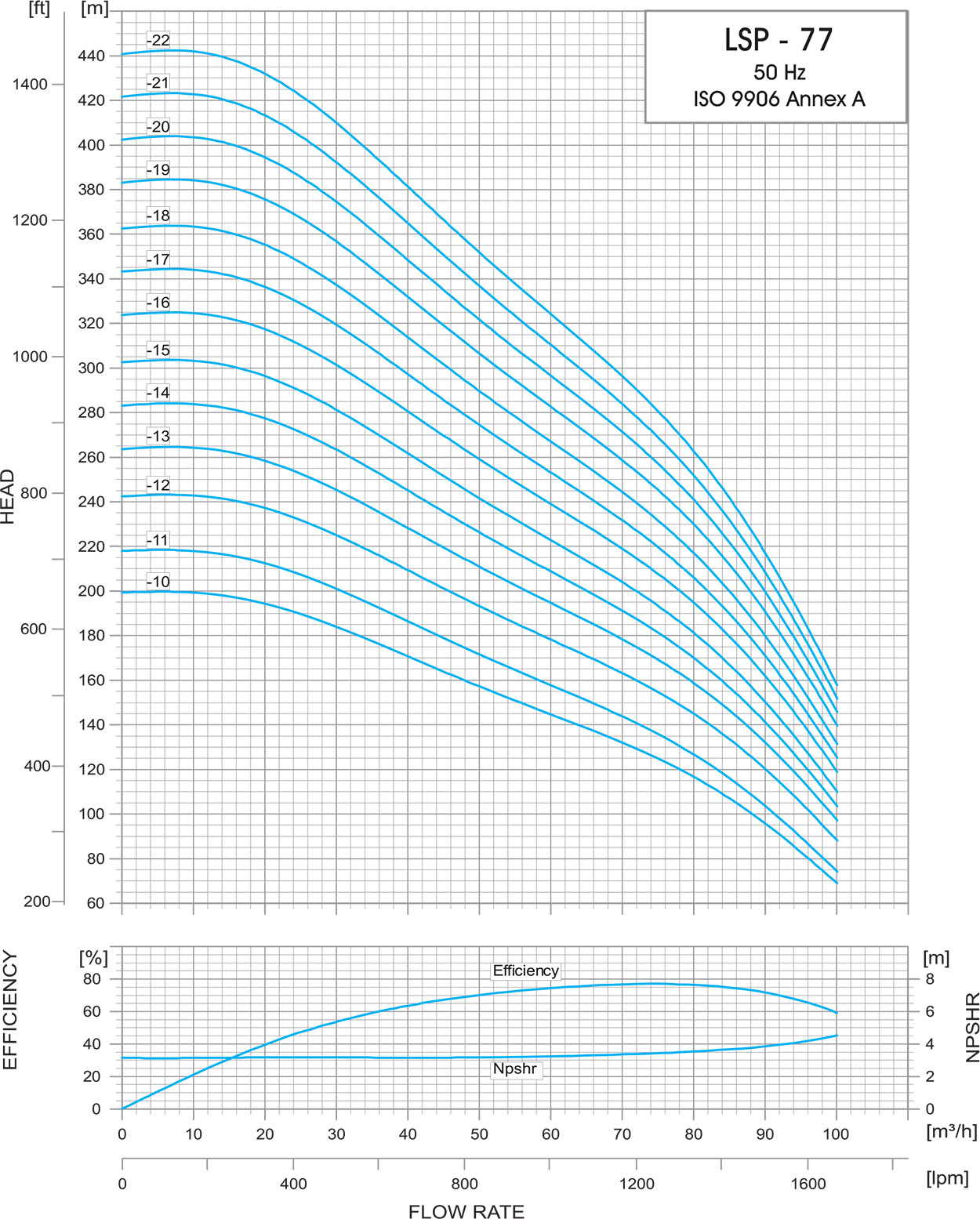

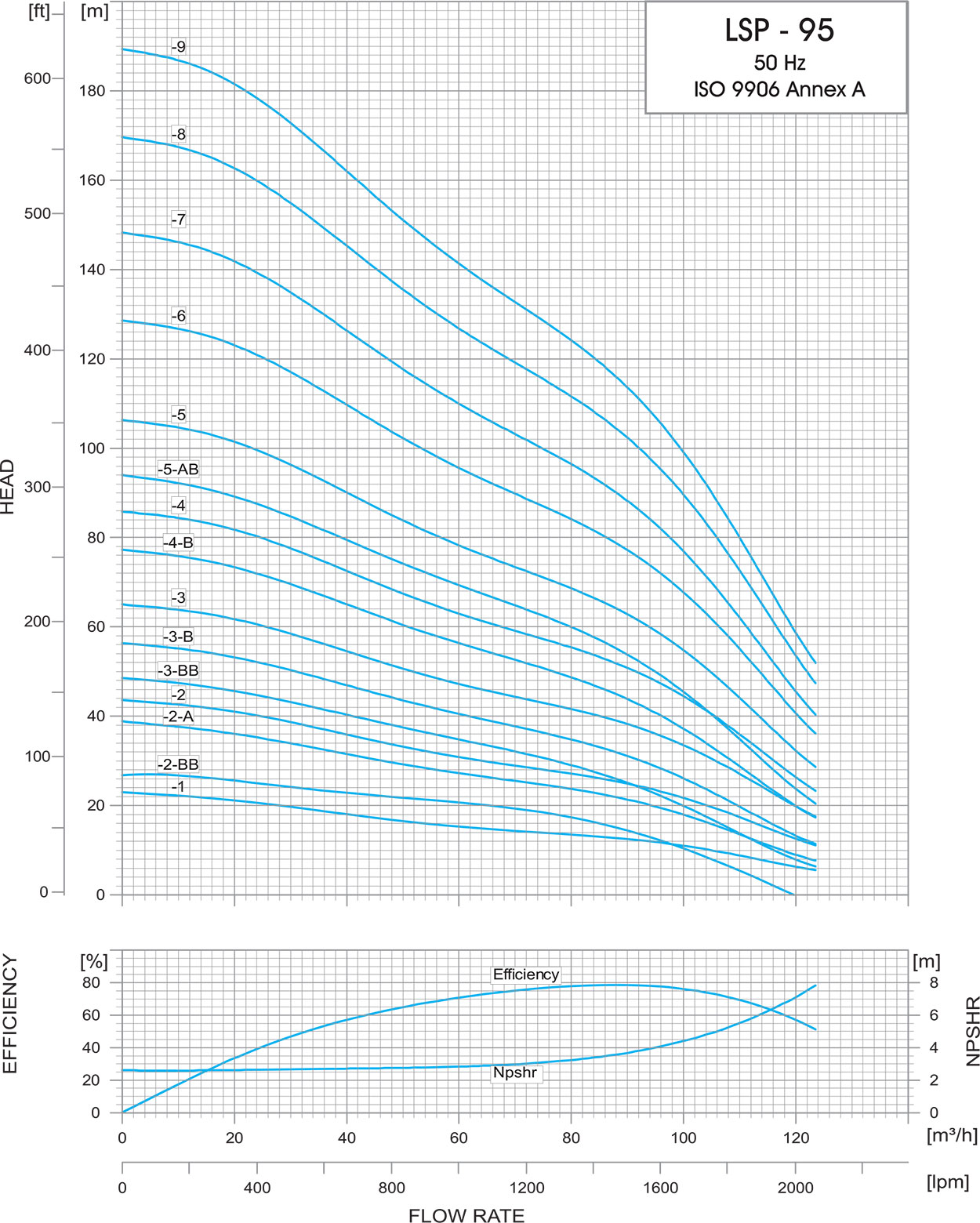

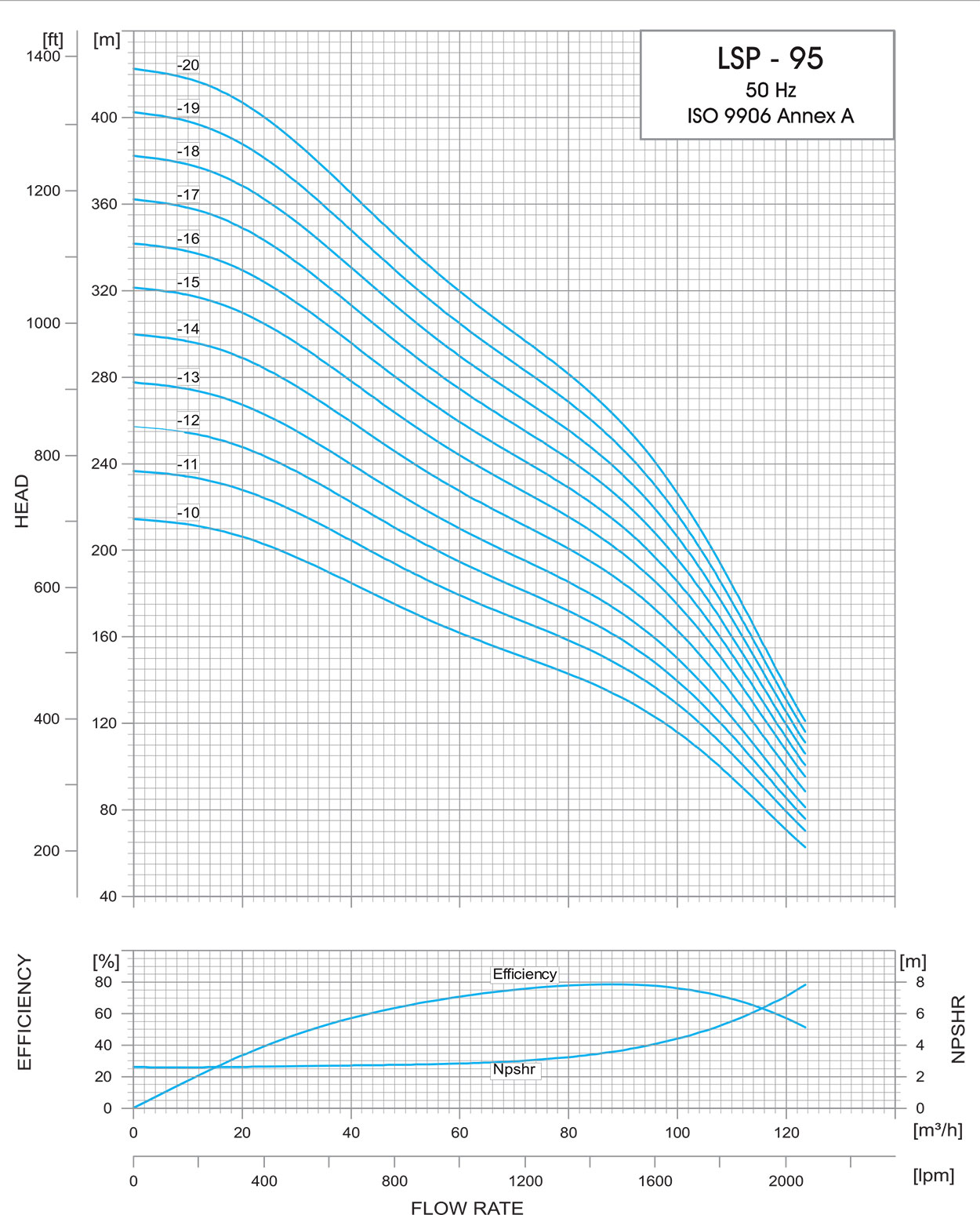

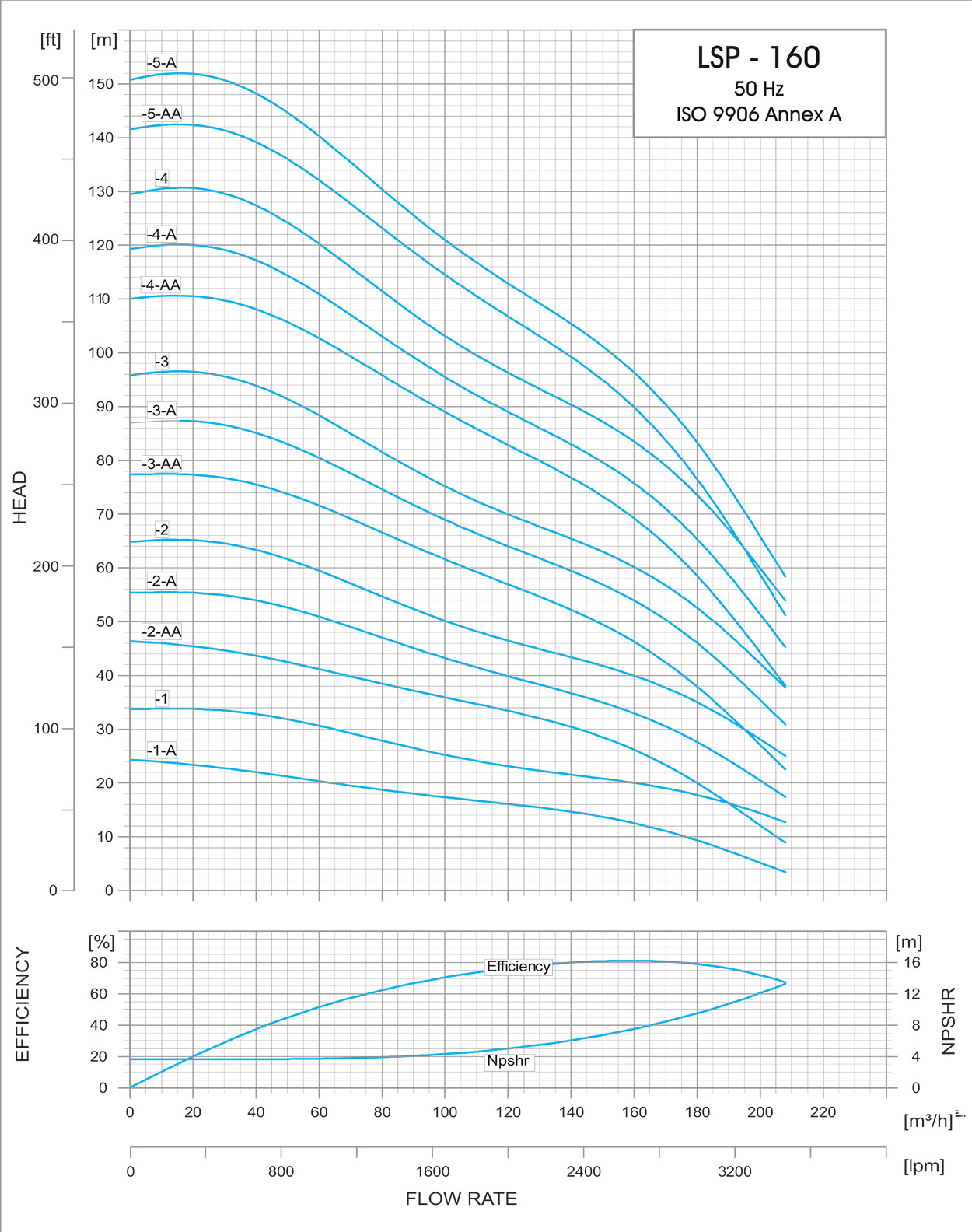

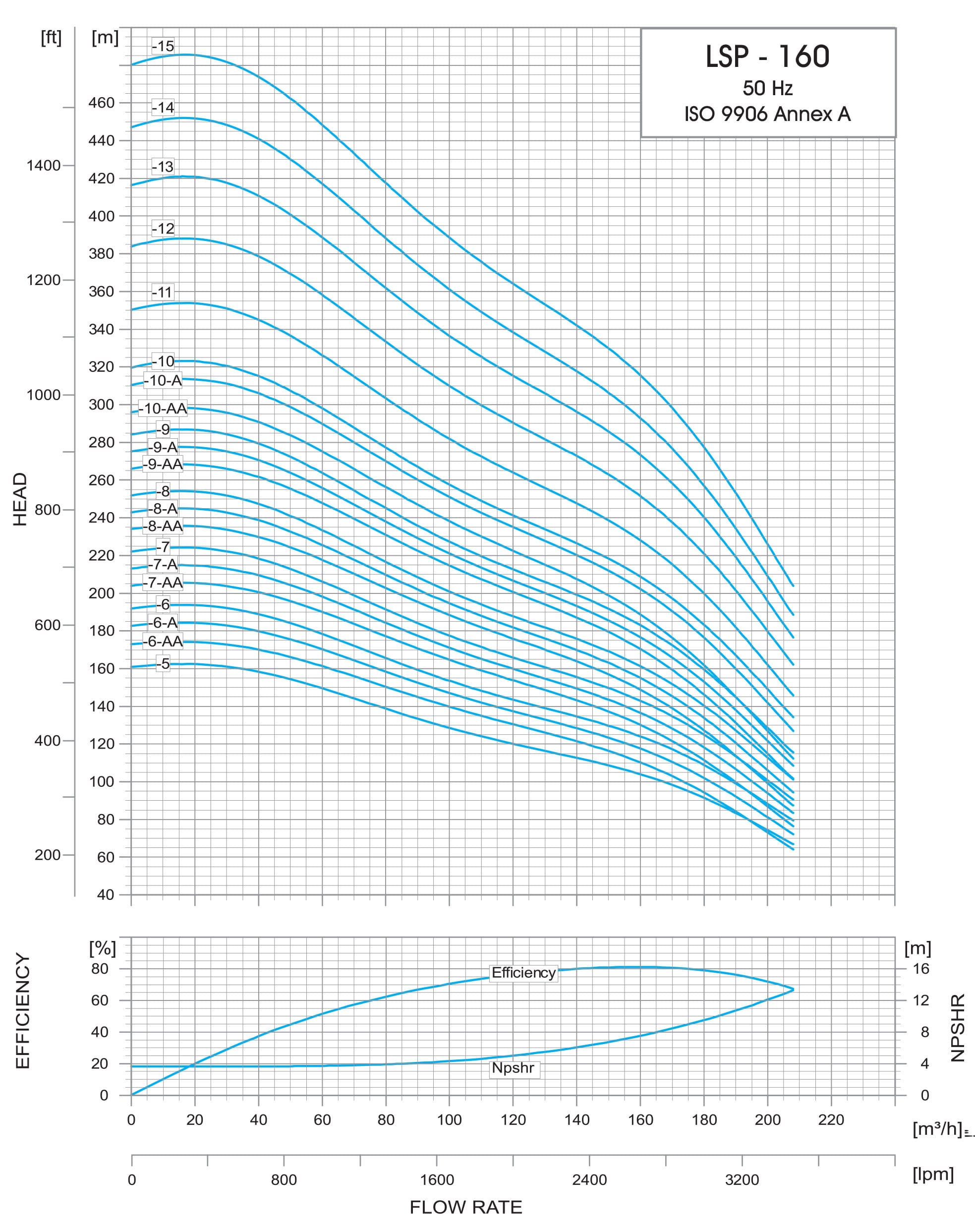

Curve Conditions

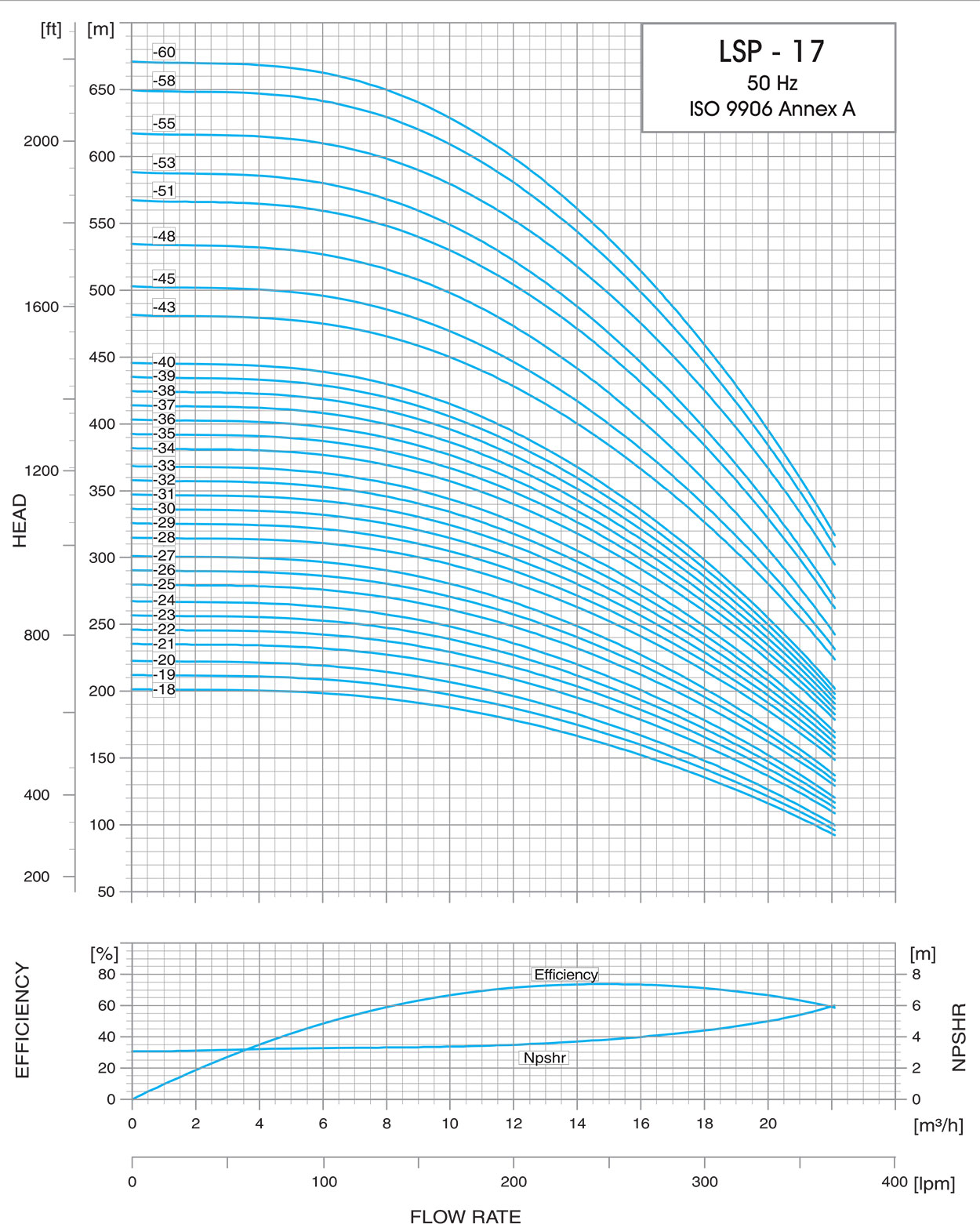

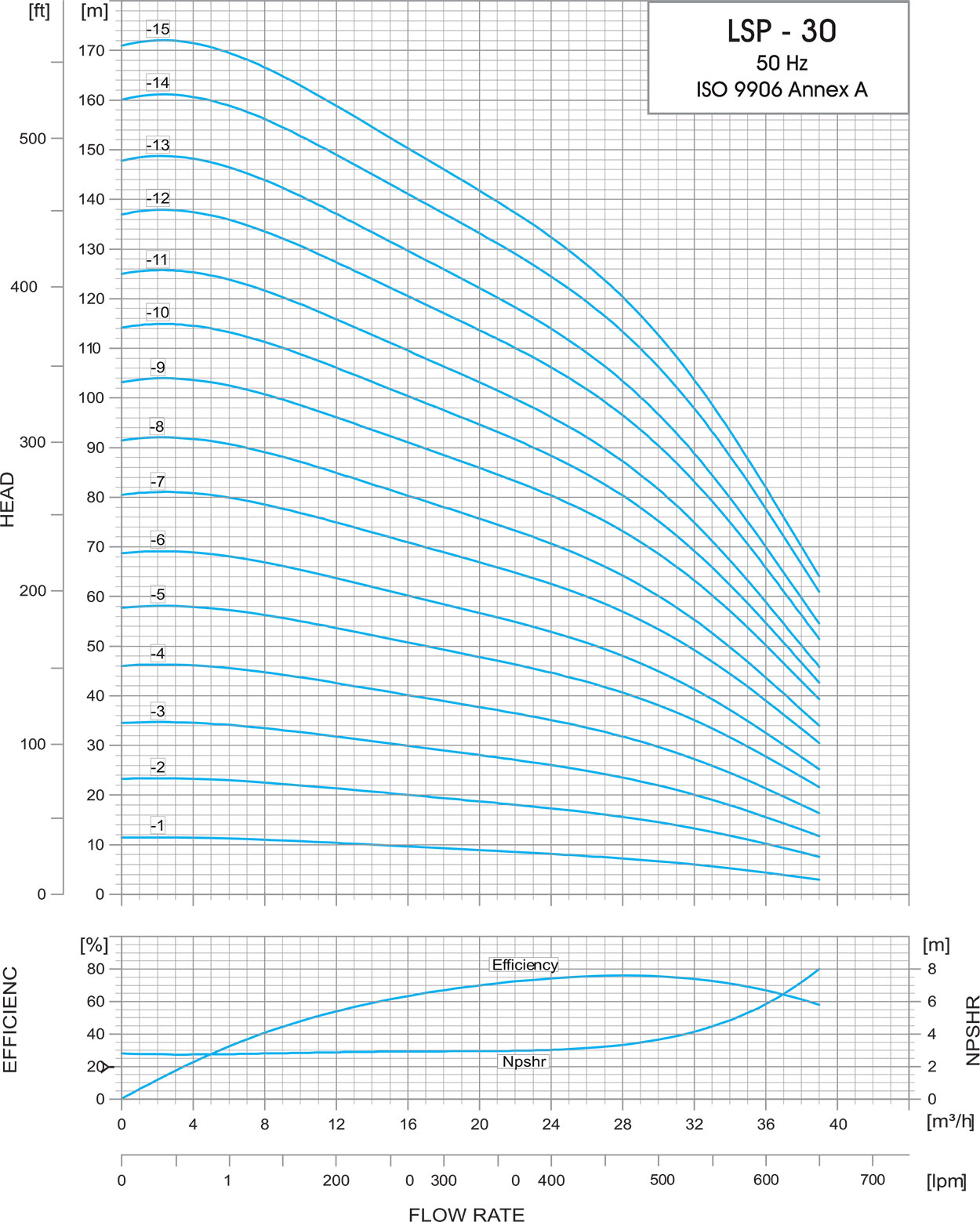

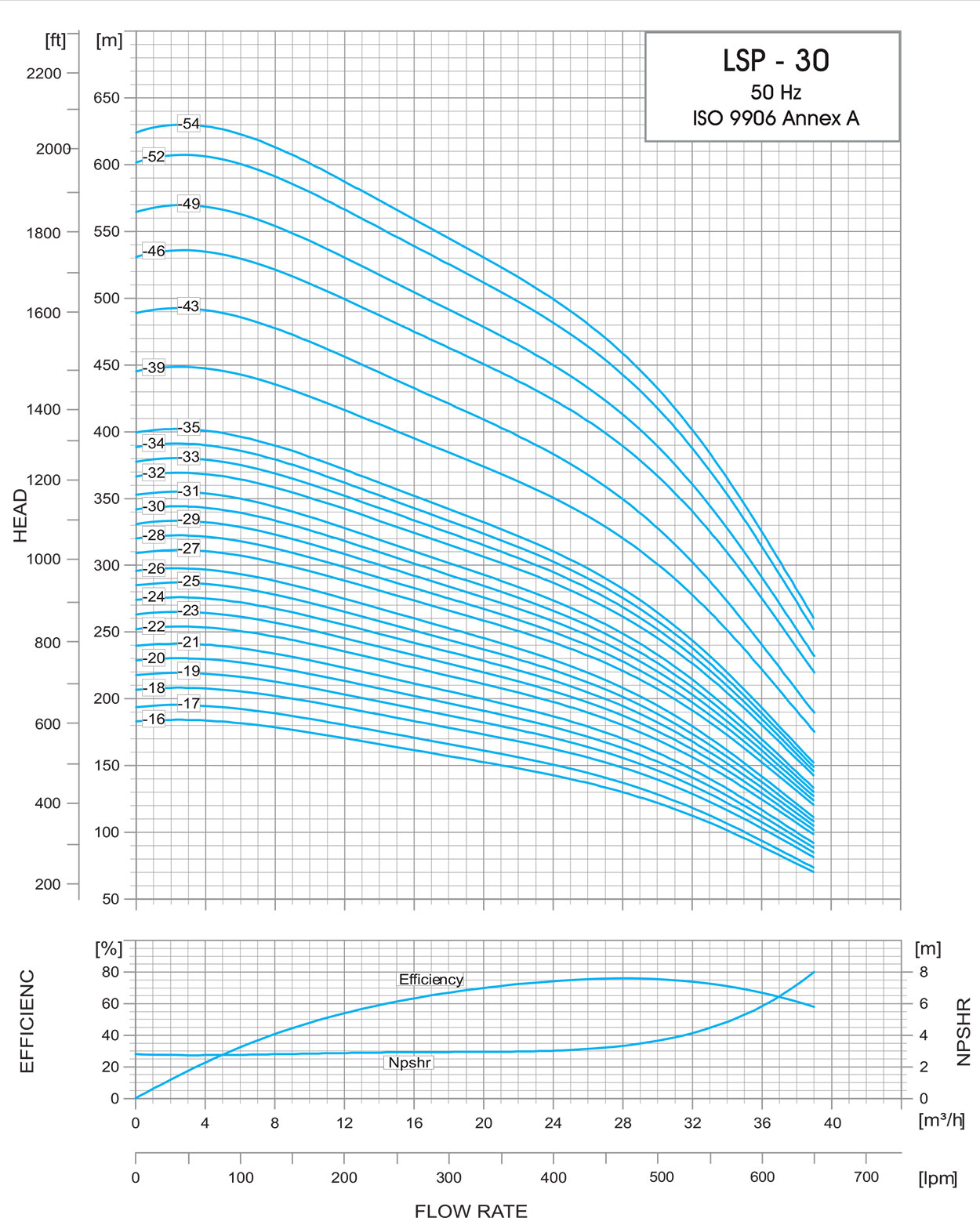

Curve tolerance acco ding to ISO 9906, Annex A

The performance curves show pump performance at actual speed cf. standard motor range.

The speed of the motors is approximately :

4" and 6" motors: n=2870 min-1

8" to 12" motors: n=2900 min-1

The measurements were made with airless water ata temperature of 20°C. The curves apply to a kinematic viscosity of 1mm²/s. When pumping liquids with density higher than that of water, motors with correspondingly higher outputs must be used.

The bold curves indicate the recommended performance range.

The performance curves are inclusive of possible losses such as non-return valve loss.

Table of Head Losses

Q/H: The curves are inclusive of valve and inlet losses at the actual speed.

Operation without non-return valve (NRV) will increase the actual head at nominal performance by 0.5 - 1.0 m.

NPSHR The curve is inclusive of suction case and shows required inlet pressure.

Power Cruve: It shows pump power input at the actual speed for each individual pump size.

Efficiency Cruve: Efficiency shows pump stage efficiency.

Features And Benefits

A Wide Pump Range

We offer submersible pumps with energy efficient duty point ranging from 10m³/hrs to 204m³/hrs. The pump range consists of many pump sizes and each pump size is available with an optional number of stages to match and duty point.

High Pump Efficiency

Often pump efficiency is a neglected factor compared to the price variations and are without importance of pump and motor efficiencies

Example

When pumping 125m³/hrs with a head of 200m for a period of 10 years $60,000 will be saved if pumps and motors having a 10% higher efficiency are chosen and the price is $0.10 per kWh.

Bearings with Sand Channels

Inlet Strainer

The inlet strainer prevents particles over a certain size form entering the pump.

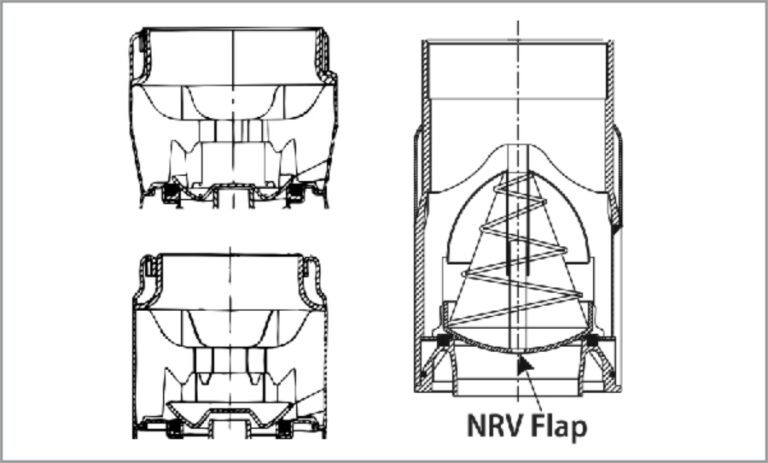

Non-Return Valve (NRV)

All pumps are equipped with a reliable non-return valve in the valve casing preventing

Furthermore, the short closing time of the non-return valve means that the risk of destructive water hammer is reduced to a minimum.

The valve casing is designed for optimum hydraulic properties, to minimize the pressure loss across the valve and thus contributes to the high efficiency of the pump.

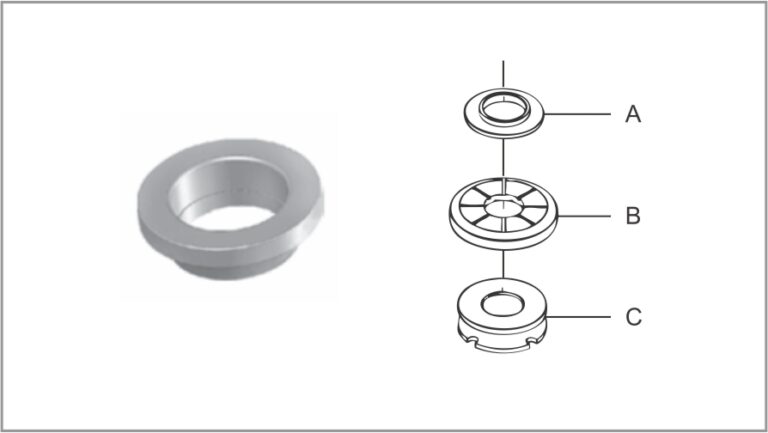

Stop Ring and Spacing Washer

The stop ring prevents damage to the pump during transport and in case of up-thrust in connection with start-up.

The stop ring, which is designed as a thrust bearing limits axial movements of the pump shaft. Example: LSP30 and LSP46

The stationary part of the stop ring (A) is secured in the top bowl (Upper intermediate chamber).

The rotating part (B) is fitted above the cullet split cone (C).

Application

We offer a complete range of pumps and motors which as a standard are made completely of stainless steel AISI-304. This provides for good wear resistance and a reduced risk of corrosion when pumping ordinary cold water with a minor content of chloride.

Low Installation Costs

Stainless steel means low weight facilitating the handling of pumps and resulting in low equipment costs and reduced installation and service time. In addition pumps will be as new after service due to the high wear resistance of stainless steel

Technical Data and Performance Curve

Performance Curva – LSP 8A

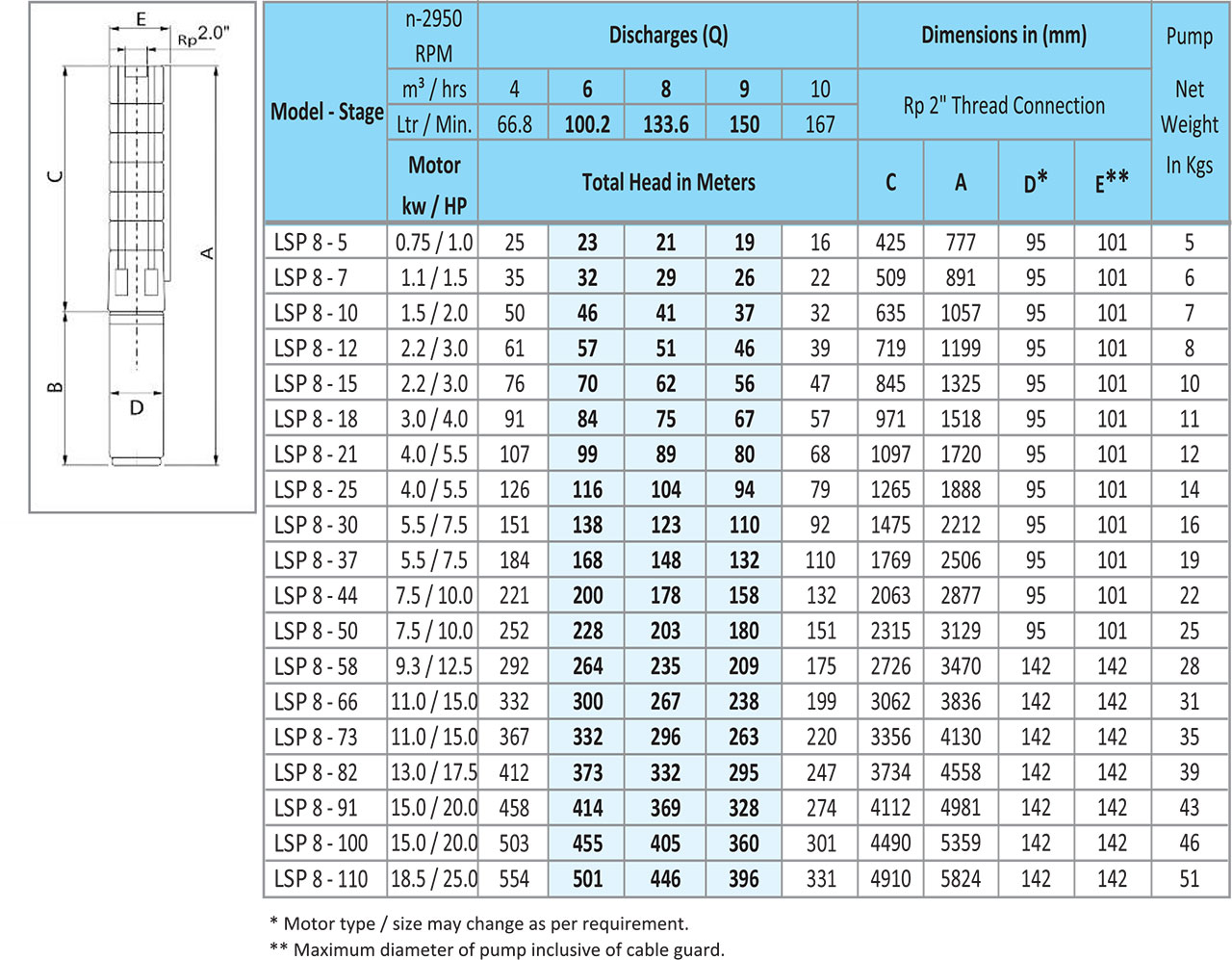

Technical Data Model – LSP 8

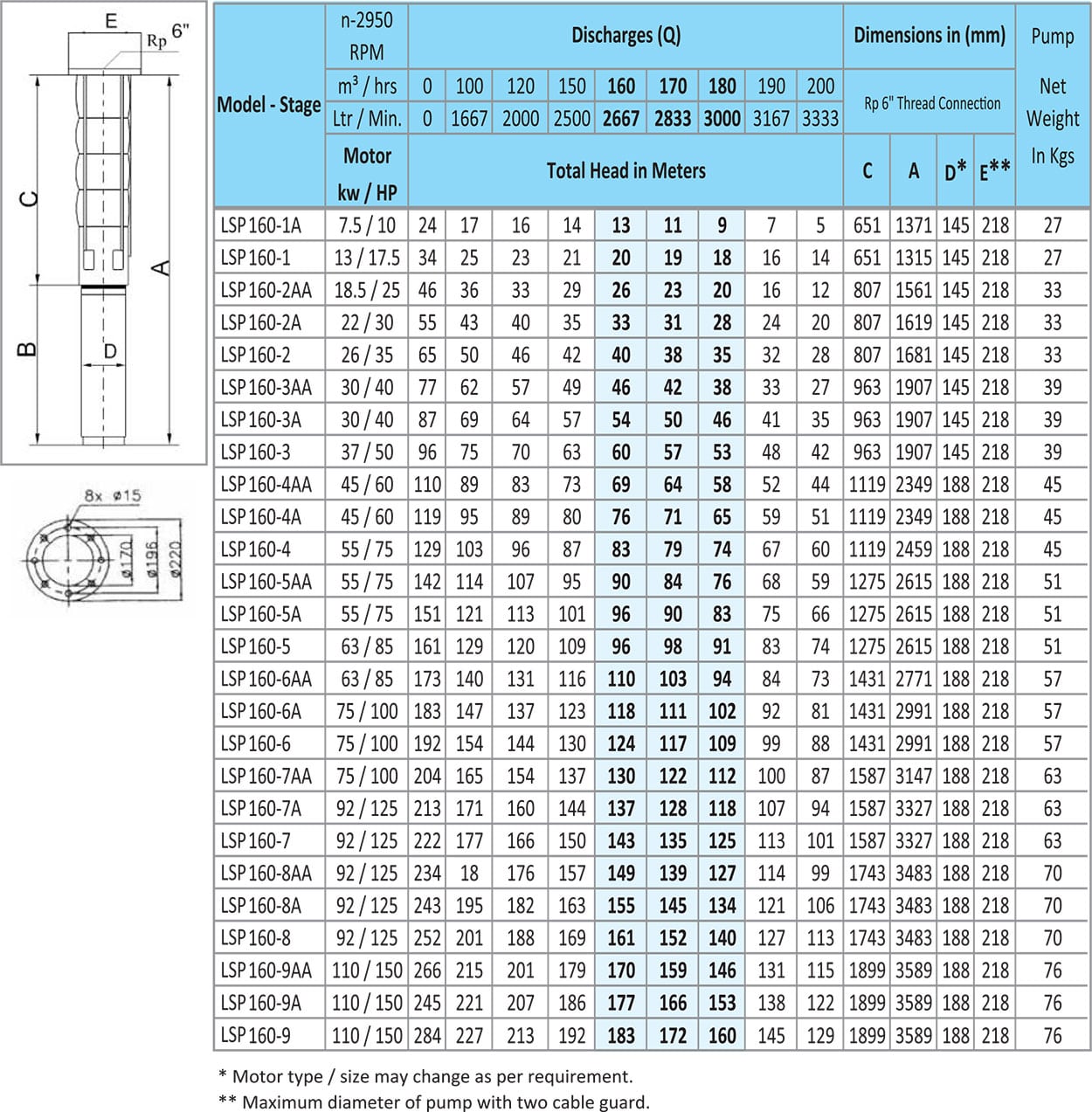

Dimension, Weight & Performance Table

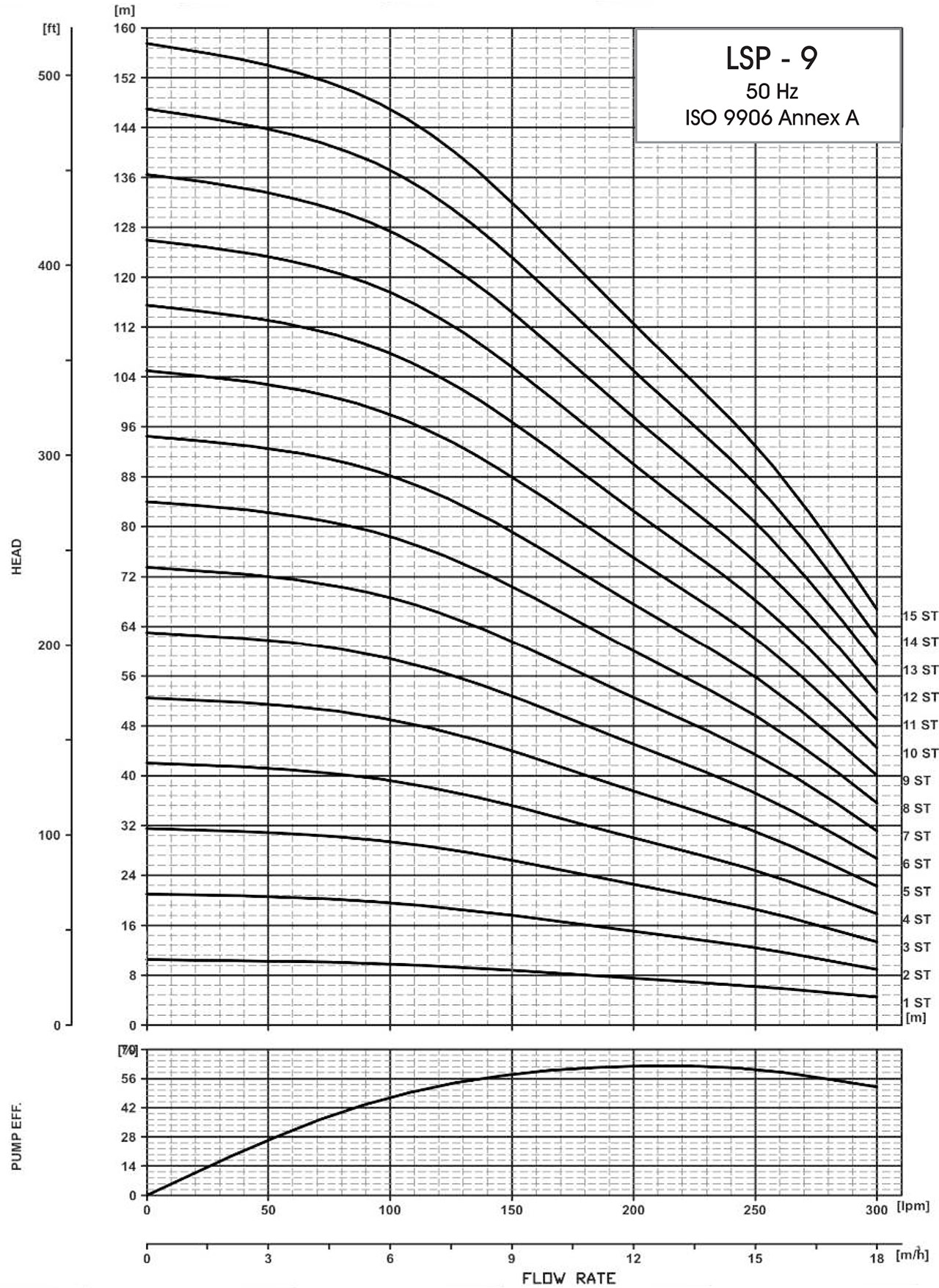

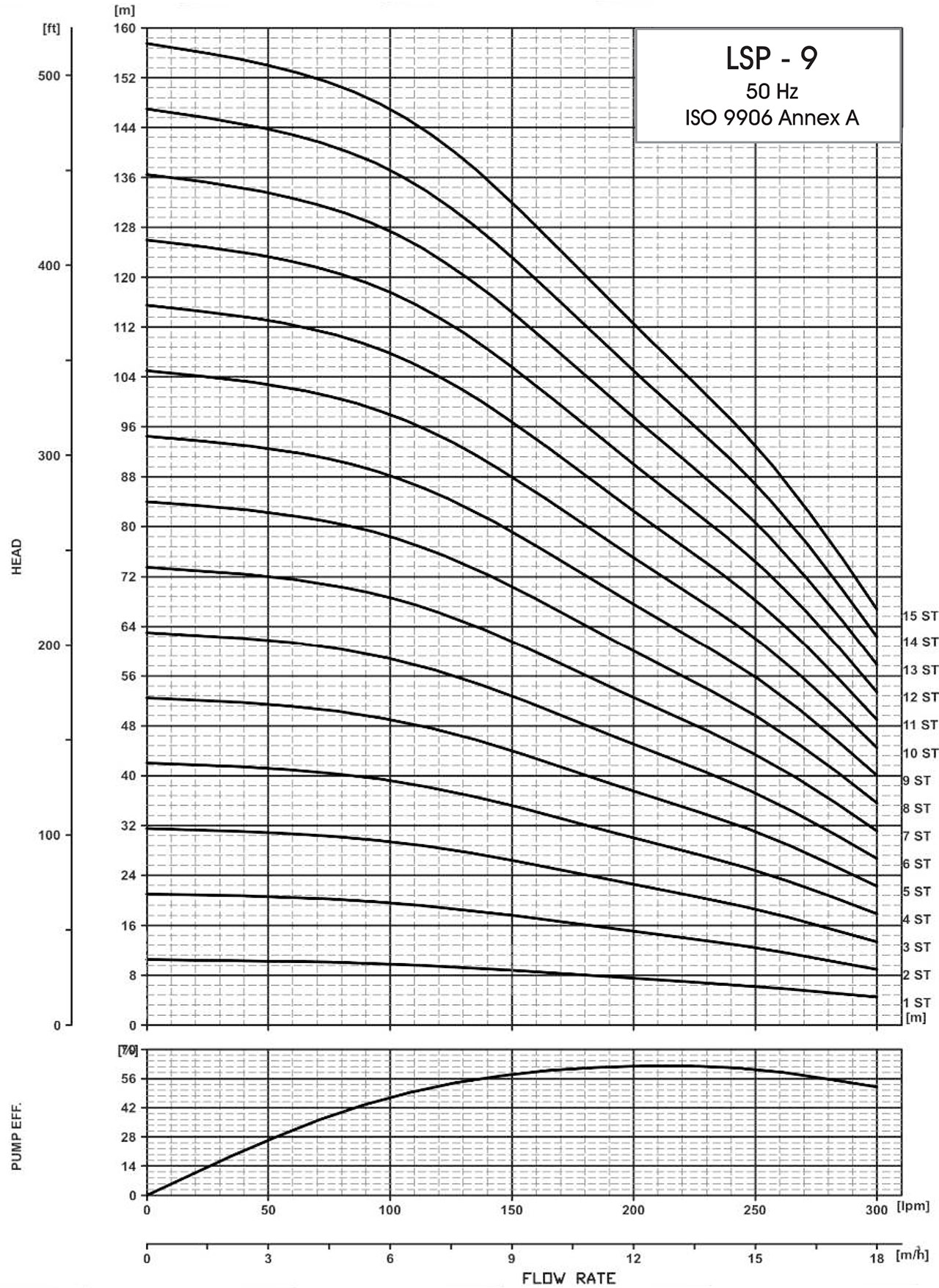

Performance Curva – LSP 9

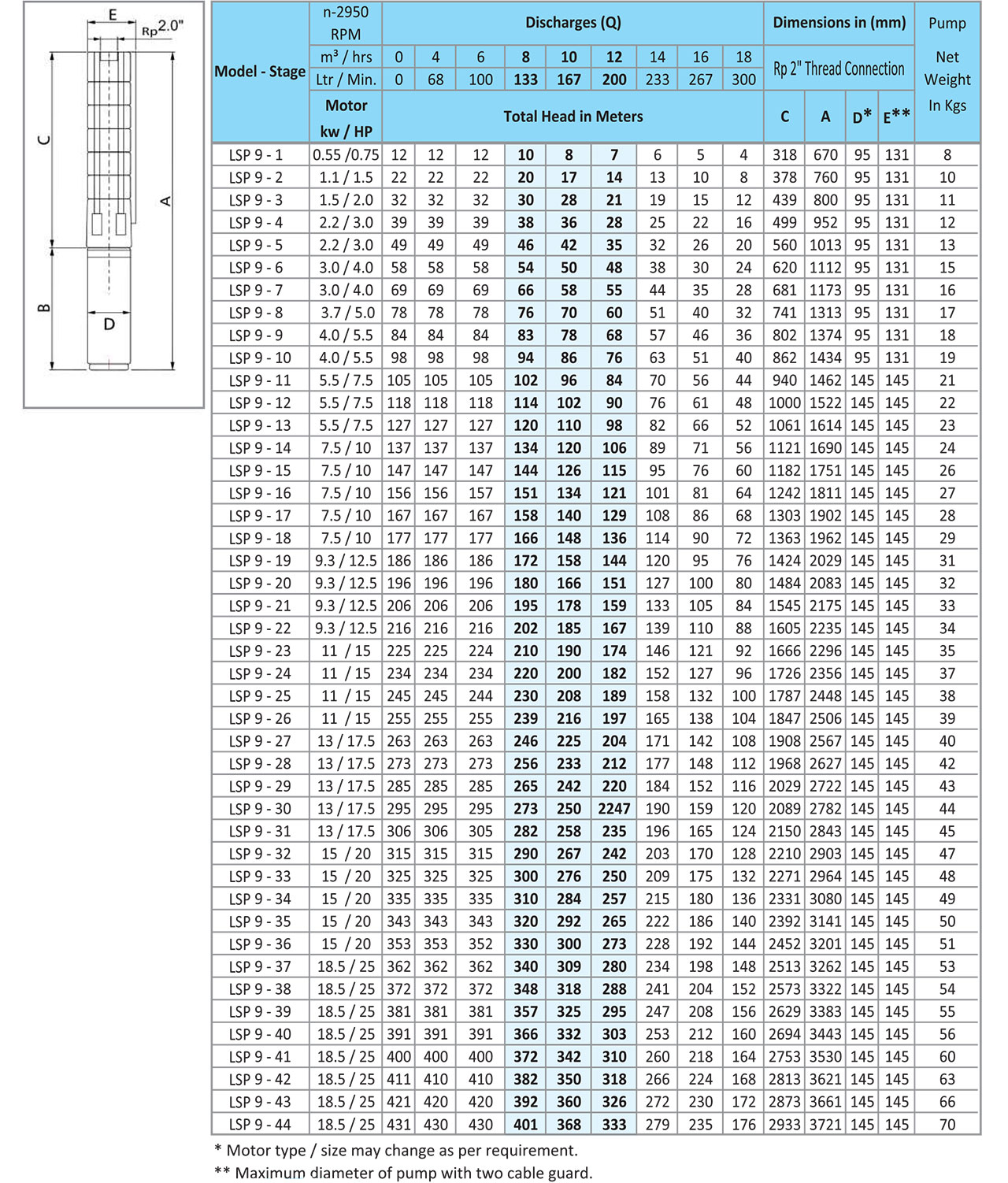

Technical Data Model – LSP 9

Dimension, Weight & Performance Table

Performance Curva – LSP 9

Performance Curva – LSP 12

Performance Curva – LSP 12

Technical Data Model – LSP 12

Dimension, Weight & Performance Table

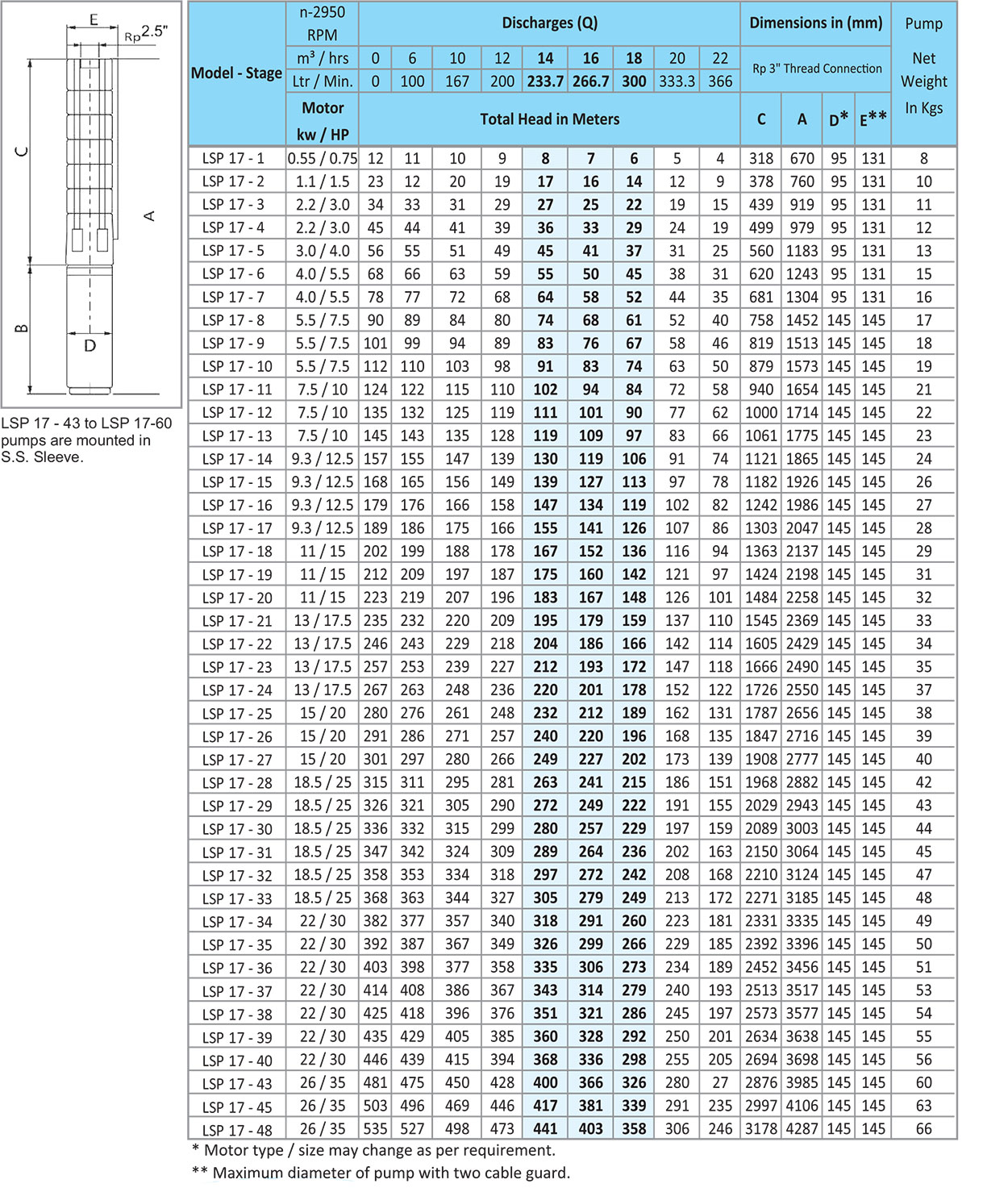

Performance Curva – LSP 17

Technical Data Model – LSP 17

Dimension, Weight & Performance Table

Performance Curva – LSP 30

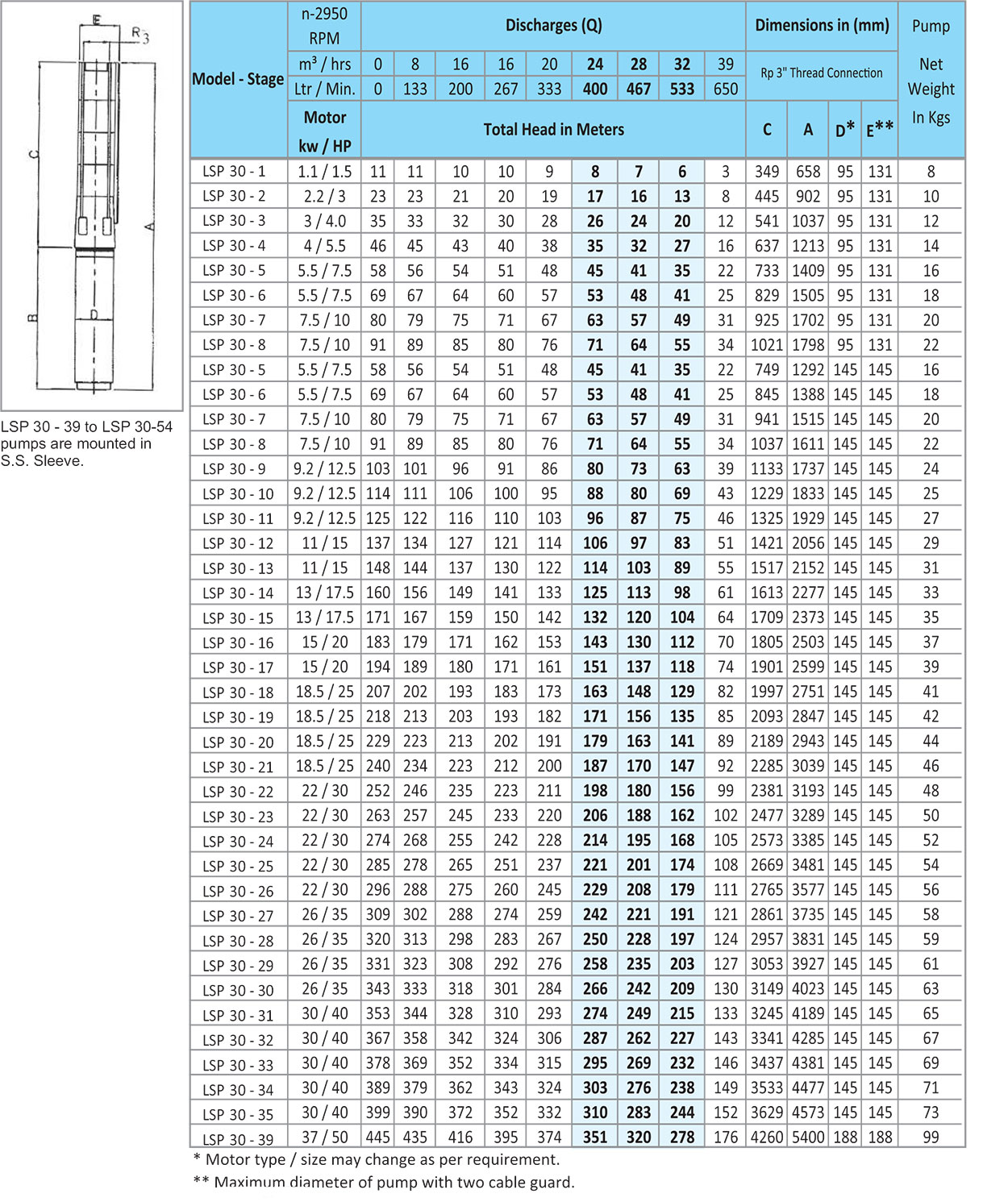

Technical Data Model – LSP 30

Dimension, Weight & Performance Table

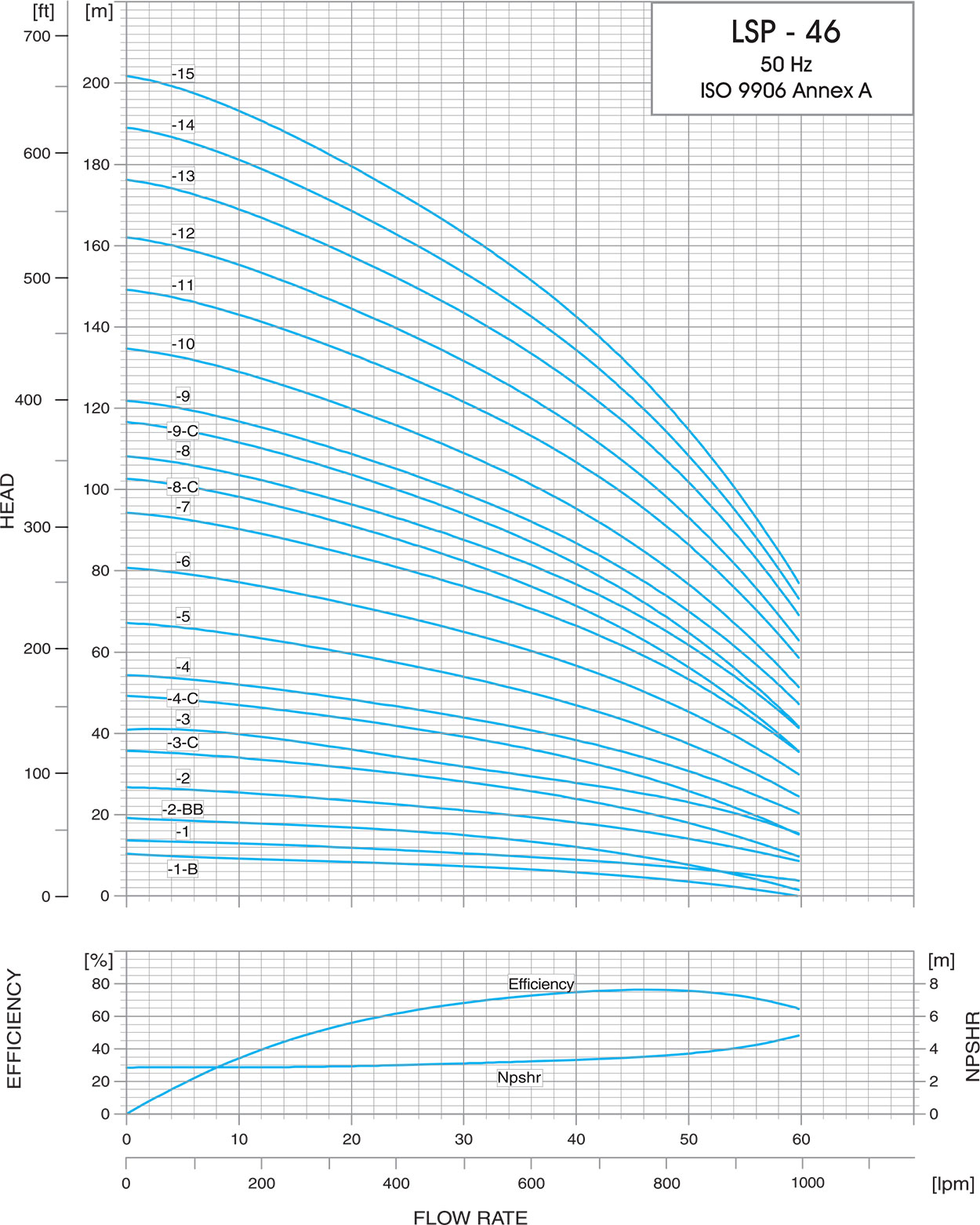

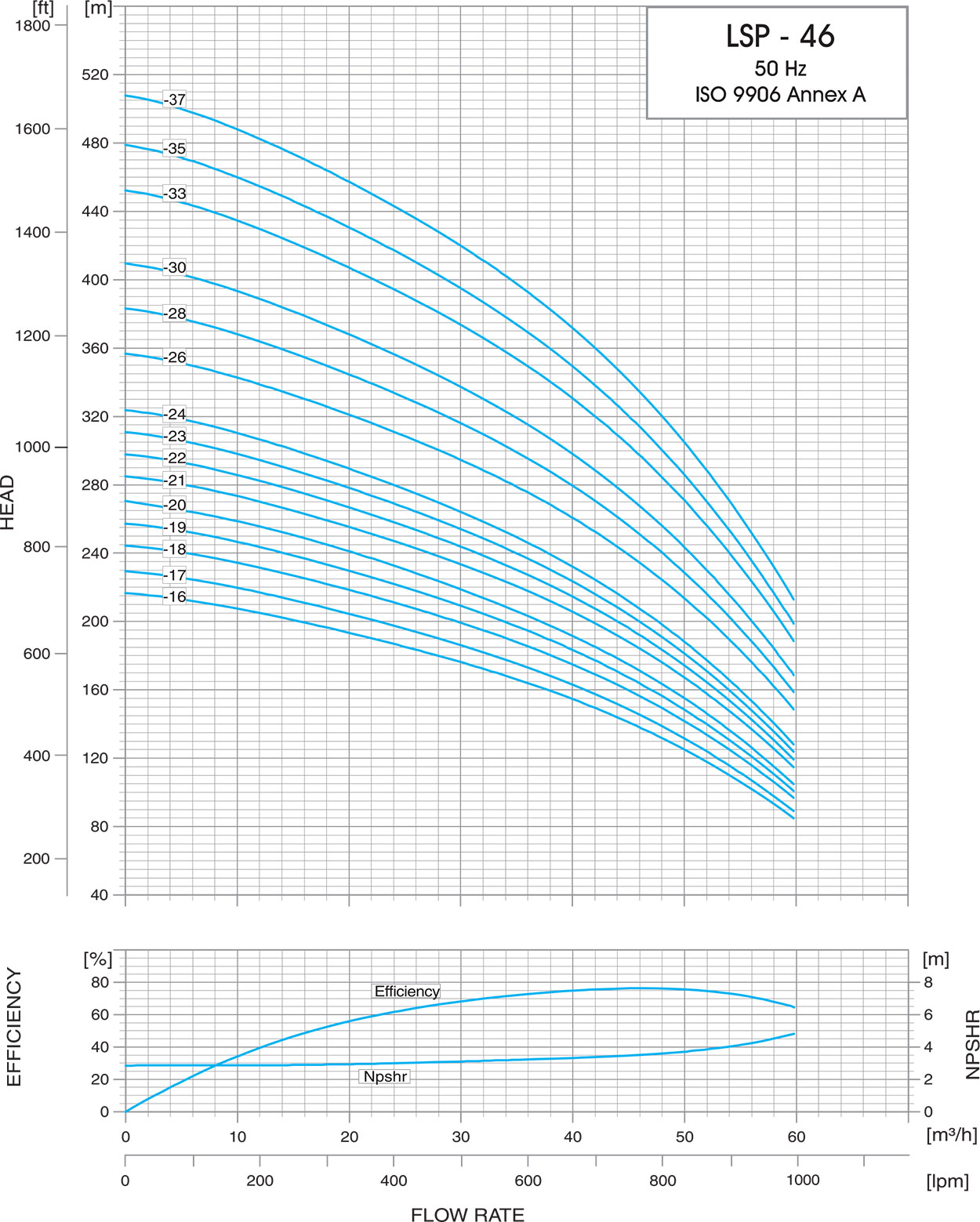

Performance Curva – LSP 46

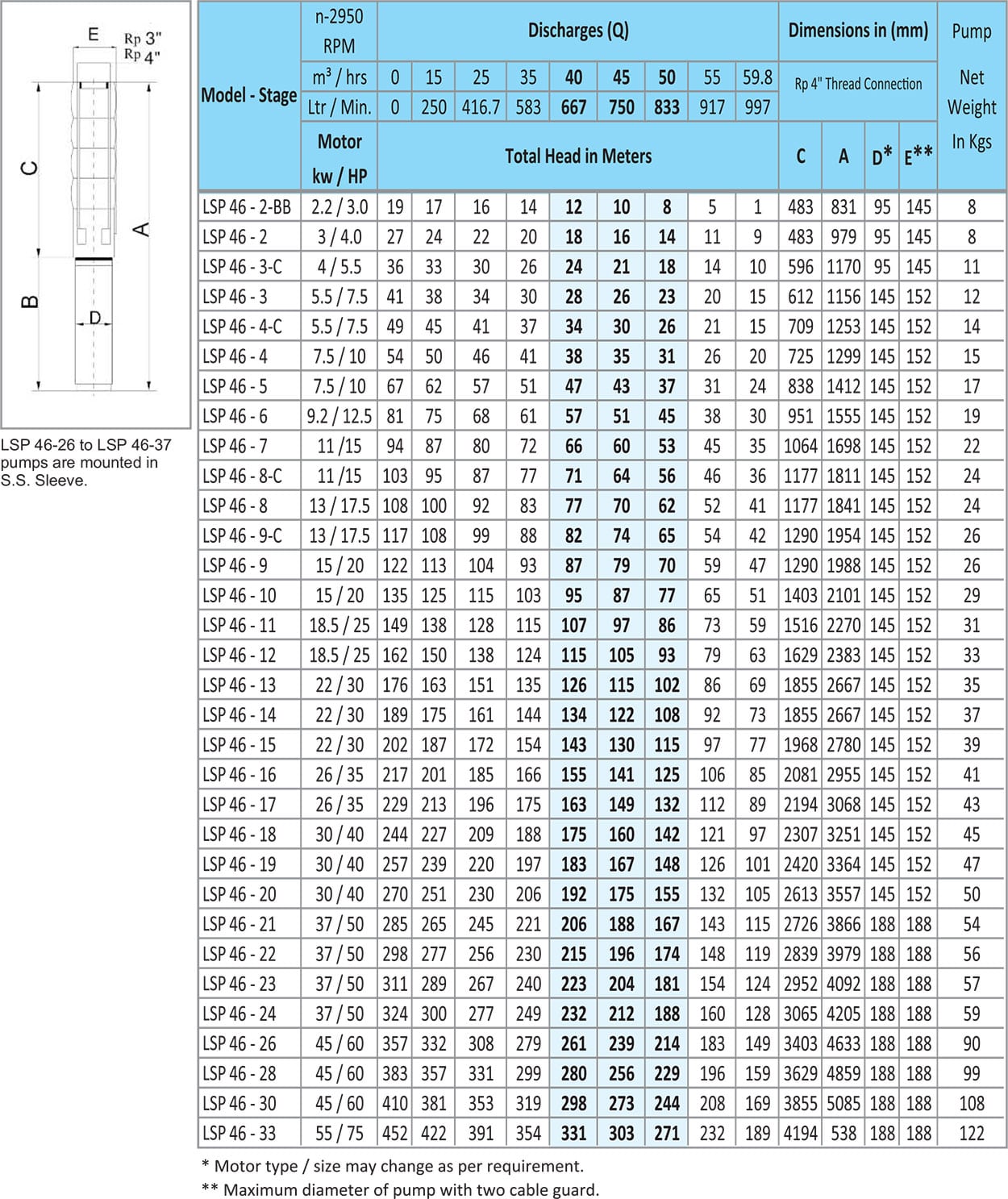

Technical Data Model – LSP 46

Dimension, Weight & Performance Table

Performance Curva – LSP 60

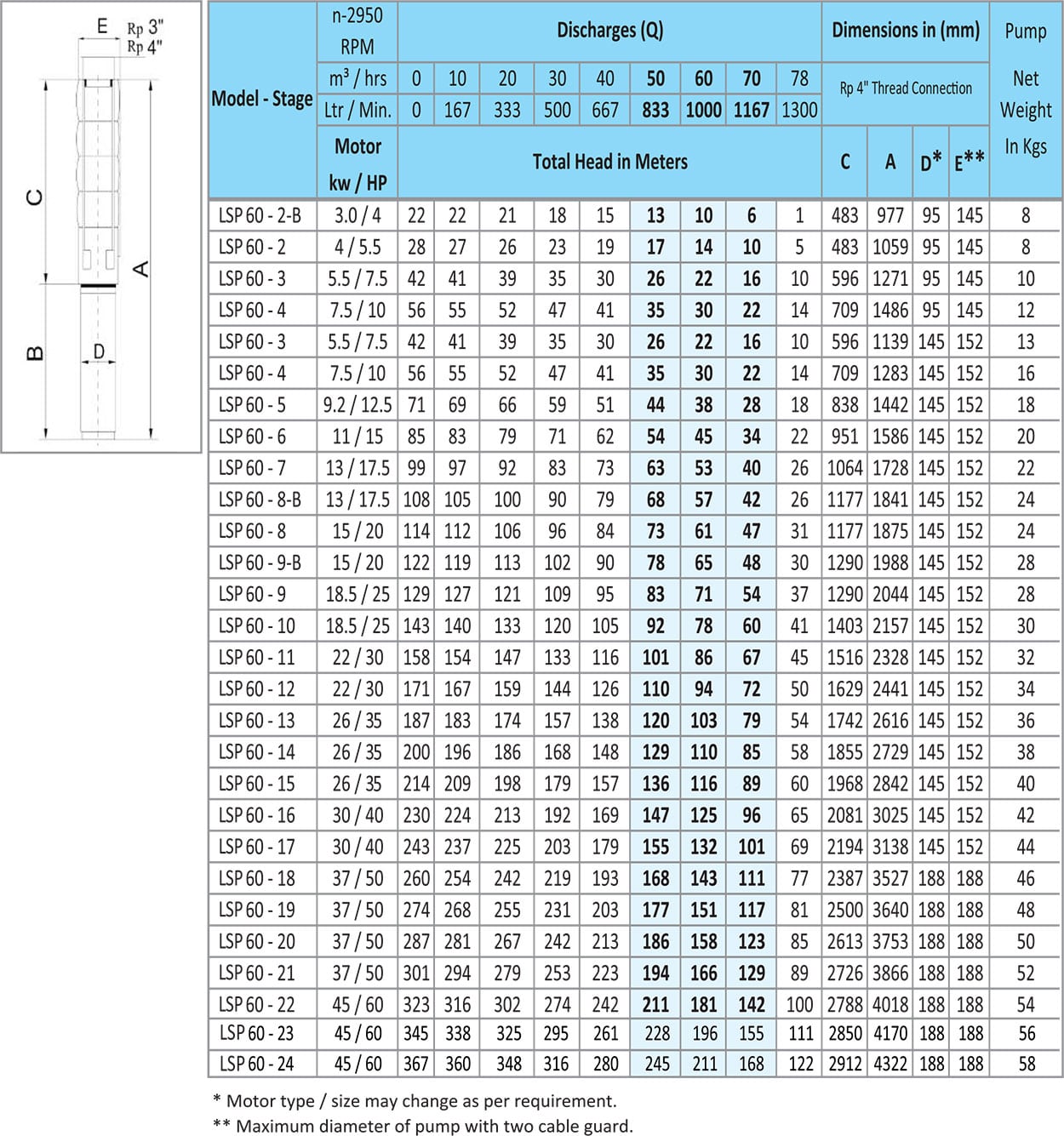

Technical Data Model – LSP 60

Dimension, Weight & Performance Table

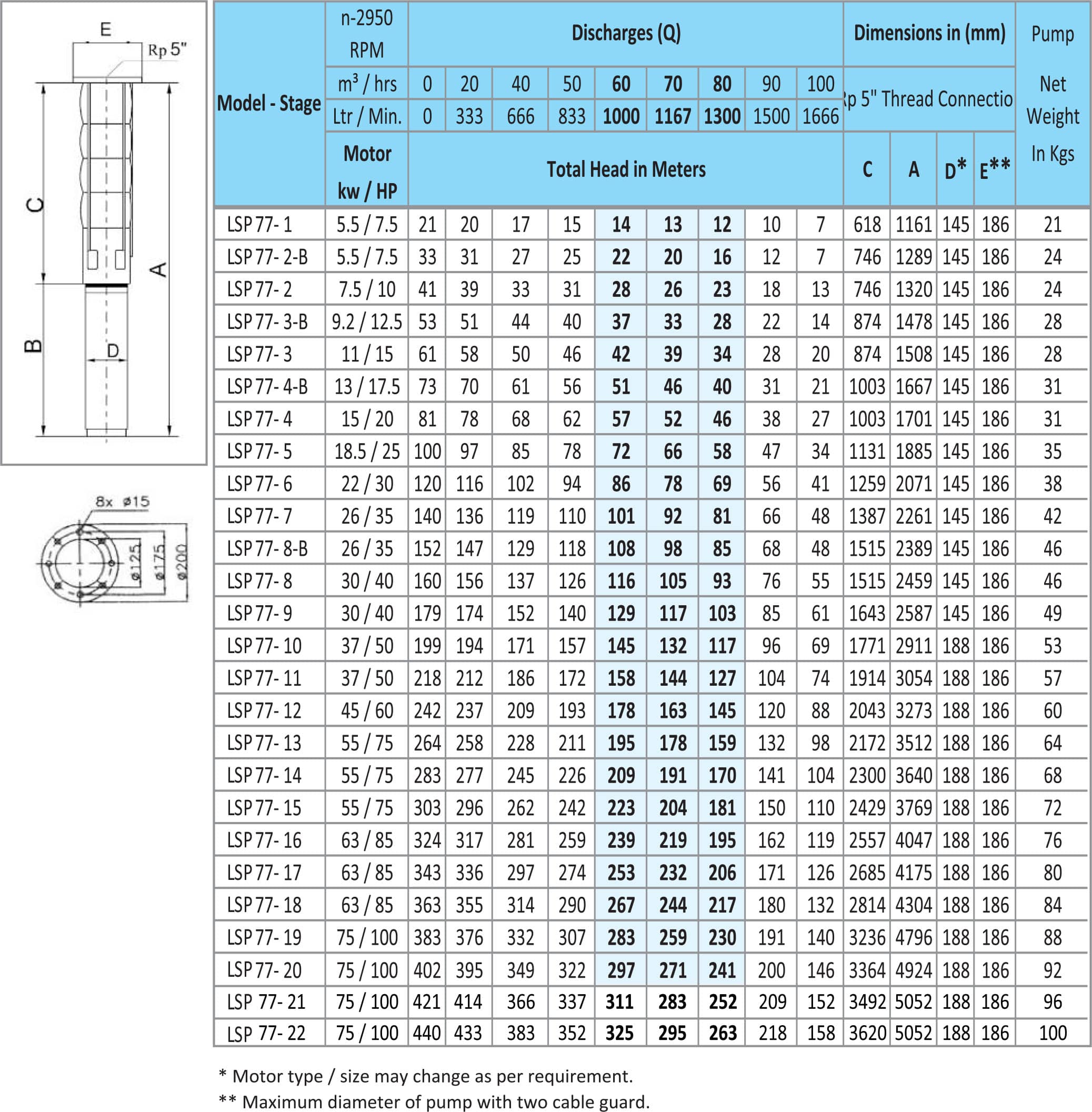

Performance Curva – LSP 77

Technical Data Model – LSP 77

Dimension, Weight & Performance Table

Performance Curva – LSP 95

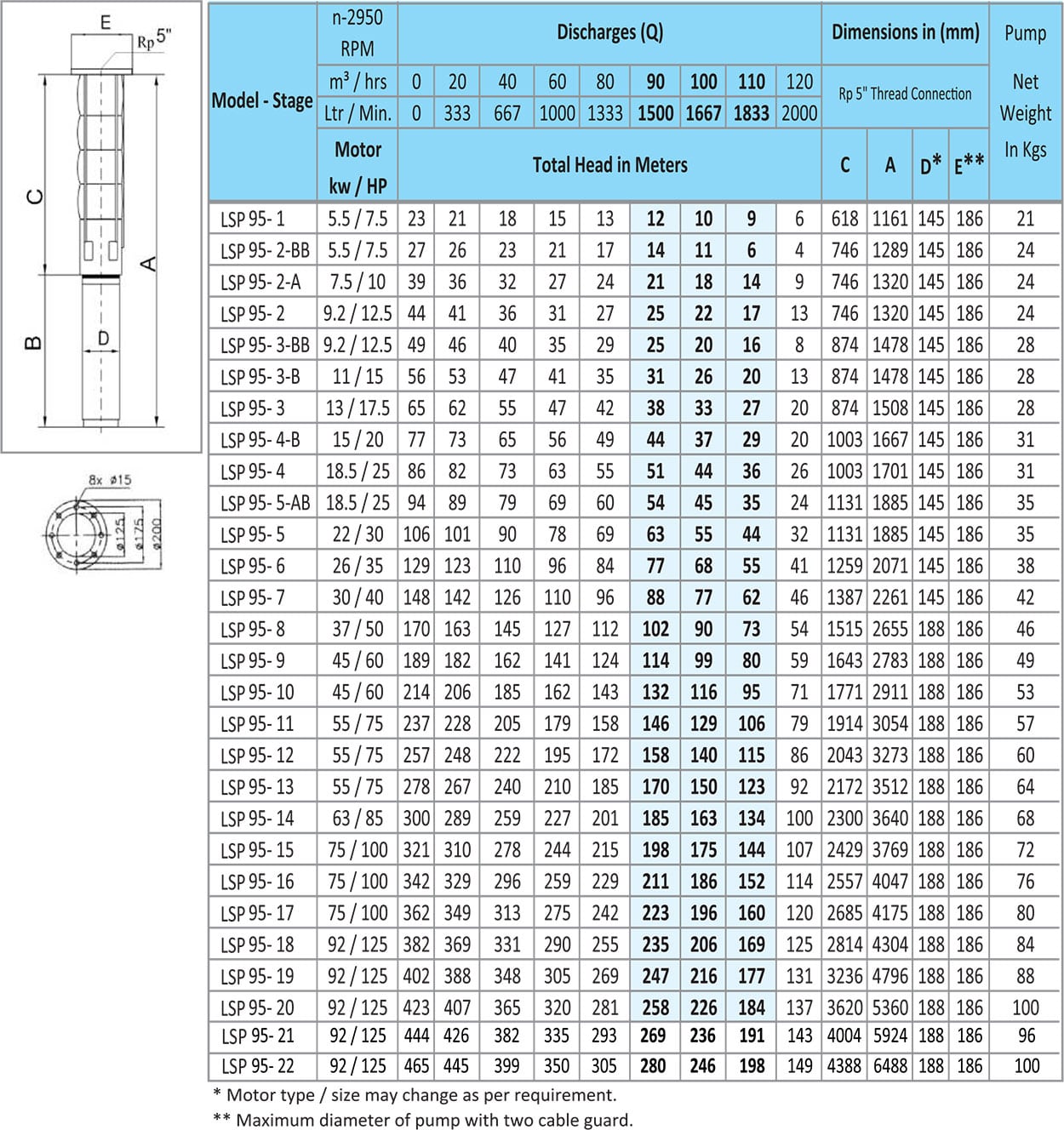

Technical Data Model – LSP 95

Dimension, Weight & Performance Table

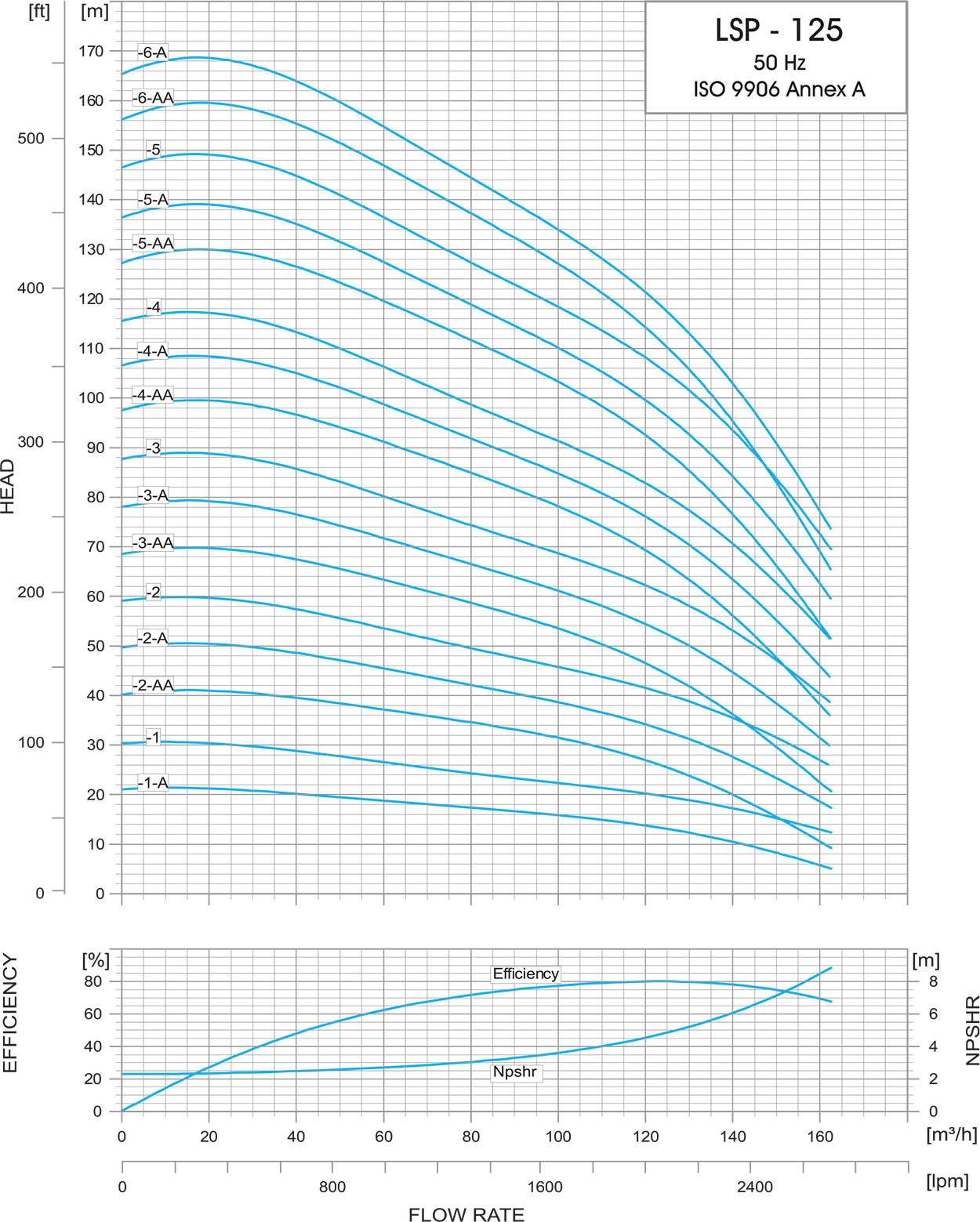

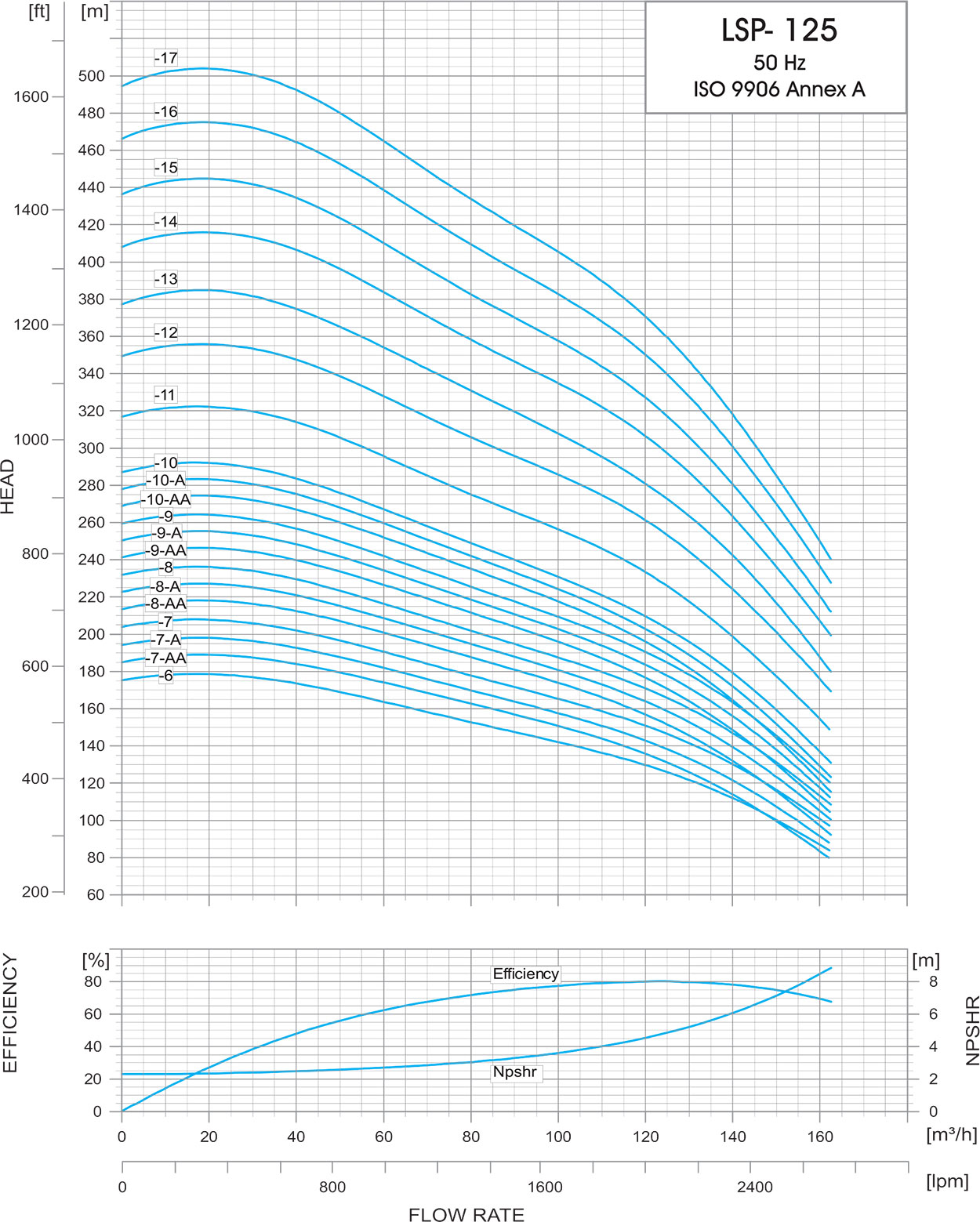

Performance Curva – LSP 125

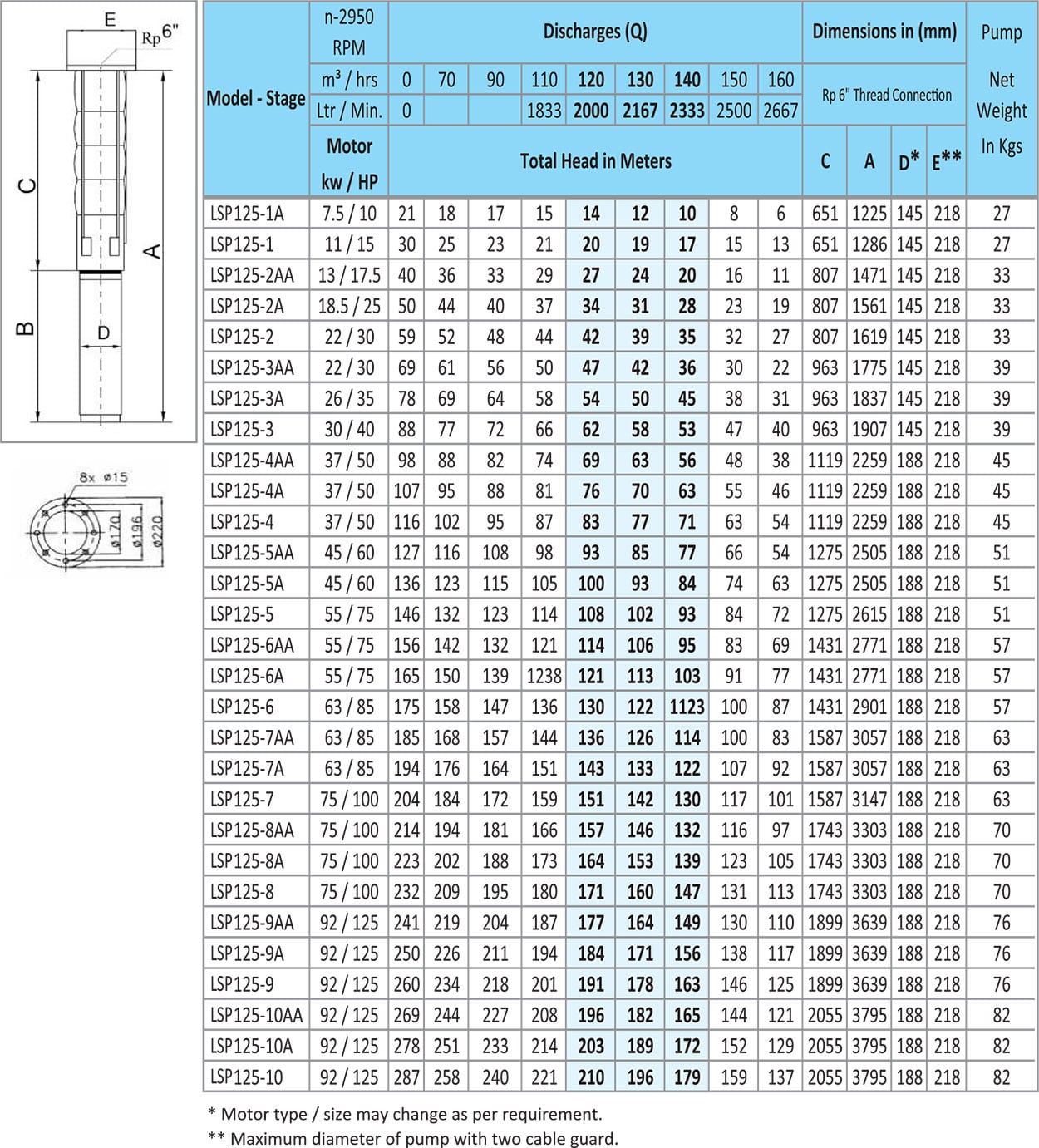

Technical Data Model – LSP 125

Dimension, Weight & Performance Table

Performance Curva – LSP 160

Technical Data Model – LSP 160

Dimension, Weight & Performance Table